![]()

Adr :636 Yunqiao Road, Pudong New Area, Shanghai, China

Phone : +86 18221614363

Email : info@zygroups.com

Tel : +86 18221614363

processing capacity:30-600

Application scope:gummy candy,hard candy

Product introduction: Small scale gummy making machine manufacturer,The depositing amount can be adjust on the touch screen,Either double color gummy or central filled gummy can be made with this machine,candy depositor machine supplier

Small scale candy making machine

1.Small automatic candy making machine

3.Gummy candy making machine-GD20-A

4.candy depositor machine-GD20S

5.Gummy candy making machine-GD20-S

6.Small scale candy production line-GD20 Max

1.small automatic gummy making machine

Name: small automatic gummy candy machine (small candy depositor machine)

Motor: servo motor

Material: 304 stainless steel

Power input: 110/220V AC/50-60HZ

Power output: 24V DC/MAX.1.5KW

Maximum temperature: 100 ℃

Application of food, pills, candy, chocolate, etc

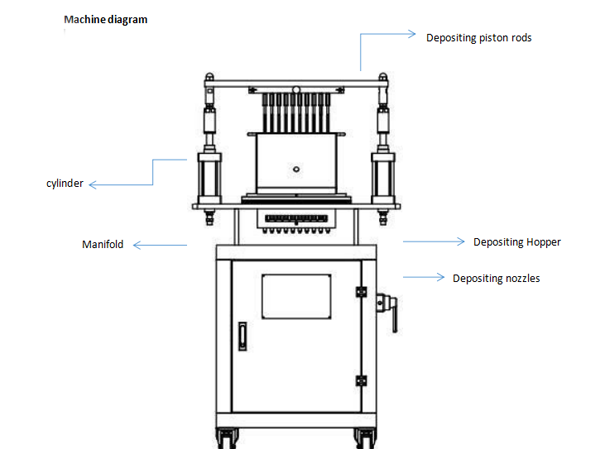

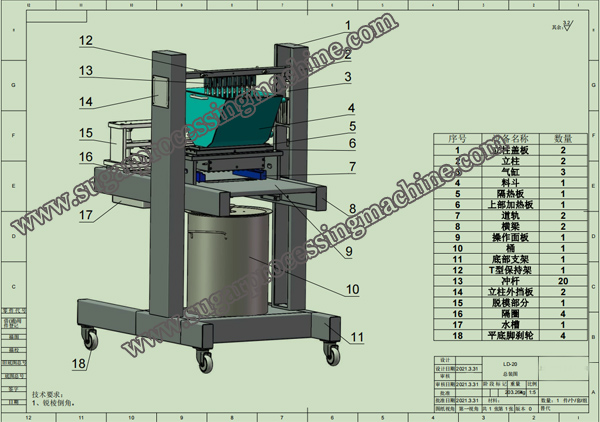

1.Gummy candy depositor machine-GD20

Machine Model: GD20

This is initial machine model, driven by cylinder, can only make solid gummy.

Manually change depositing quantity.

Machine Materials: Stainless steel 304.

Depositing nozzles: pure cooper

Electrical components: Siemens - Germany

Cylinder : Airtac - Taiwan,China

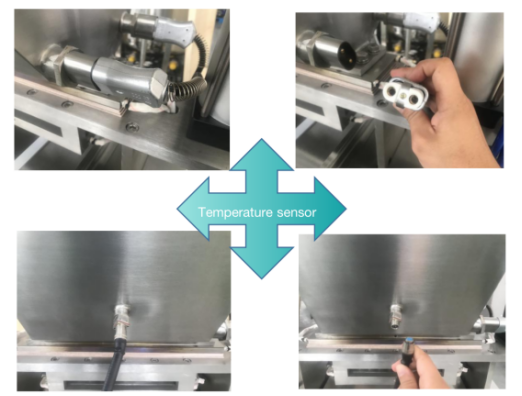

Temperature sensors: Omron -Jacky

Voltage :380V 50HZ,3PH

Strike speed :30times/min

Depositing quantity:1-10g

Hopper volume: 23L

Consumption of air 20CBM/min

Power:7.2kw

Dimensions:800*800*1700mm

Machine details

The hopper is processed by CNC without any sanitation dead angel. Easy to wash .

The hopper has two layers with conduction oils

20 piston nozzles are all made of pure copper for better heat transfer effects

Piston rods are easily removed for cleaning.

The position of each piston rod can be adjustable (up and down), make different dosing quantity possible

Temperature control and display.

Hopper / Manifold / Nozzles are all be detected with temperature display.

Operation Manuel

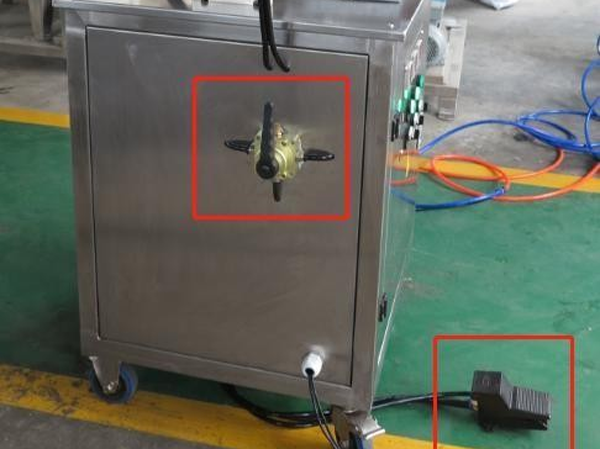

1.connect compressed air and power. Turn on the depositing machine, set the temperature as required.Depositing is driven by cylinder, control the depositing amount by adjusting the piston travel.

2. Add syrup to the hopper manually.

3. put mould under the hopper

4,Turn on depositing button or step on the pedal

5.demoulding by hand after the gummy is dry.

2.Gummy candy making machine-GD20-A

Machine Model: GD20-A

GD20-A equipped with demoulding device

Water wash structure

3.candy depositor machine-GD20S

Machine Model: GD20S

GD20S is equipped with servo motor on the basis of GD20

The depositing amount can be adjust on the touch screen

Either double color gummy or central filled gummy can be made with this machine

All operation are done on the touch screen.

4.Gummy candy making machine-GD20-S

Machine Model: GD20-S

Easy to operate ,clean and maintain

Hygienic design,stainless steel construction,and programmed washout cycle allow quick and thorough cleaning for the fast cleaning for the fast changeover,and there is easy access for maintenance

Simplicity is a decisive benefit with all operator actions prompted by instructions on the HMI screen

Servo control system produces consistent shape and piece weight as well as precisely controlled dosing of active ingredients. Products have a high-quality appearance and long shelf life

5.Small scale candy production line-GD20 Max

Machine Model:Small scale candy production line GD20 Max

All design, components, structure all in full compliance with European standard.

Production:

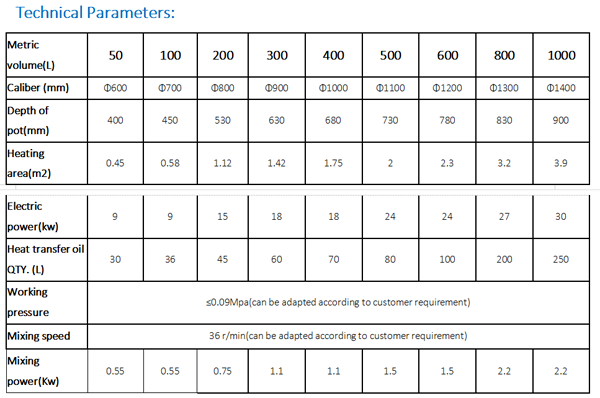

Tilting jacket cooker is composed of kettle, bracket, worm wheel and worm etc. The cooker can revolve with 180°,The equipment is used for open concentration, mainly for decocting and concentration of liquids in industries of pharmaceutical industry, food industry, chemical industry and light industry etc. Contact area of the equipment with materials is made of stainless steel SUS304,which has perfect corrosion—proof performance, and is highly endurable according to GMP requirements. Blender also can be added according customer requirements.

Features:

This kind of jacketed kettle has the following features:

1. Easy to install and operate;

2. Uniform Heating;

3. Large heating area;

4. Short boiling time;

5. Easy control of heating temperature;

6. Mixing scrapers can touch the bowl thoroughly avoids burning;

7. Stirring speed is adjustable;

8. Corrosion & abrasion resistance;

9. Longer service life;

Classification of Jacket Cooker:

By heating method:

1. Electric heating type;

2. Steam heating type;

3. Gas(pls indicate LPG or natural gas) heating type

By configuration of the Jacketed Kettle:

1. Tilting type / vertical type;

2. With agitator / without agitator;

3. ordinary stirring type / planetary stirring type;

4. With lid / without lid;

Note: 50L is a special customized model

Jacket Cooker Samples:

All rights reserved:Zhi Yan Group Co., Ltd SitemapSitemapCandy making machine candy production line Toffee production line biscuit production line lollipop production line Gummy production line Popping boba production lineManufacturer