![]()

Adr :636 Yunqiao Road, Pudong New Area, Shanghai, China

Phone : +86 18221614363

Email : info@zygroups.com

Tel : +86 18221614363

processing capacity:50-800kg/h

Application scope:gummy,jelly candy,hard candy,Lollipop,milk candy fruit,Toffee candy etc

Product introduction: Automatic gummy making machine can make gummy,hardy candy,jelly candy,Lollipop,milk candy fruit,Toffee,xylitol candy etc

Gummy production line is divided into gel gummy production line and starch mold colloidal gummy candy production line

small semi-automatic gummy machine

4.Starch Gummy Candy Production Line

3-Depositor gummy candy starch mogul line

Semi-automatic jelly candy starch mogul line

6.Working principle of gumm making machine

7.Installation of the gummy making machine

8.How to choose the gummy machine and price

Large gumm production line

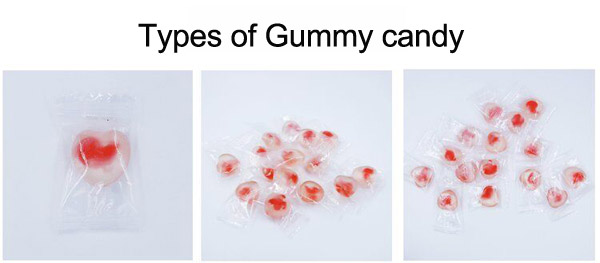

The gummy-making ingredients can be gelatin pectin carrageenan agar etc. The candy production line is designed to meet food safety and GMP standards. With the use of different configurations, this production line produces single color gummy candy, two-color gummy candy, striped gummy candy and other gummy candy types.

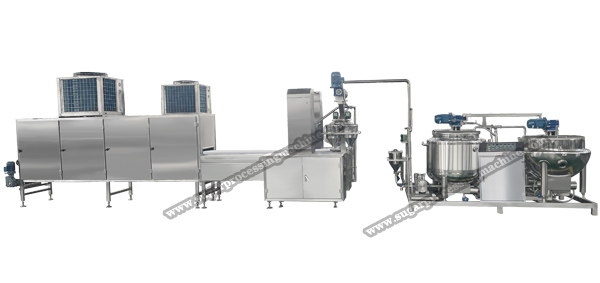

Large gummy candy production line

Large gummy candy production line :which can produce gummy with multiple shapes and variety colors on base of advanced technology process. It is an ideal machine to produce superior quality gummy candy of single color and double color; By change-over molds or depositors, different color and different shape of gummy can be also produced. The on-line mixer achieves the quantitative dosing and mixing of the flavor, color and acid. High degree of automation can produce super quality of gummy, at the same time it saves the manpower and the

Flow of gummy making machine

Jacket cooker-Mix tank-Lobe pump-Storage tank-Depositor-Cooling tunnel-Oil spray-bagging machine

Main machine of gel gummy

1.Jacketed cooking kettle

The jacketed cooking kettle is used to dissolve and cook ingredients such as glucose, granulated sugar, and water. It uses electric heating and features a large heating area, heating uniformity, and easy to control the temperature. This equipment improves product quality and shortens the processing time.

2.Gummy mold

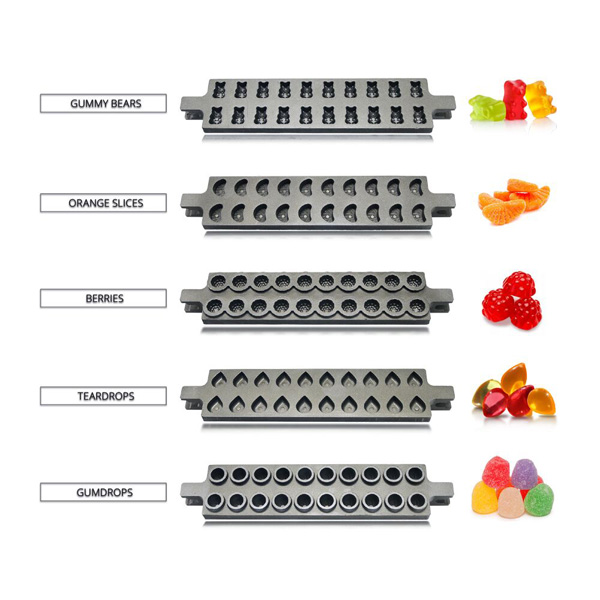

The production line manufactures candies in a variety of shapes using different molds. We will design molds according to your needs.

3.Gummy Depositing machine

The depositing machine uses PLC to control the parameters such as temperature and depositing speed. These parameters are easy to read and set on the touch screen, while the syrup flow is precisely controlled via a frequency control system to ensure a stable sugar paste quality.

4.Dissolving and mixing unit with automatic weighing system(Optional)

5.Oil spray machine(Optional)

This machine is used to spray oil on the gummy candy before or after it has been dried for a glossier surface. It is applied to different gummy candy types.

6.Sugar coating pan(Optional)

The sugar coating pan is used to coat a sugar icing on gummy candy before or after it has been dried. It is used for different gummy candy varieties.

7.Self-stacking tray and cart(Optional)

After the gummy candies are formed, they will be stacked in self-stacking trays that are stacked layer by layer, then sent via a cart to the drying room.

Large gummy production line video

Model:ZY800Q

Capacity:800kg/h

Candy weight:According to the size of candy

Depositing Speed:25-55n/min

Working condition:20-25,C temperature humidity 55%

Electric power needed:39kw/380v

Total Length:25m

Weight of machine:8200kg

Flow of gummy making machine

Jacket cooker-Mix tank-Lobe pump-Storage tank-Depositor-Cooling tunnel-Oil spray-bagging machine

Features

The flavors and color mixing system uses a dosing pump and dynamic mixer manufactured by LM to ensure the mixed syrup is uniform in color. The food coloring and flavoring amount is adjustable according to your needs.

The improved depositing head is more reliable and accurate.

The punch is easy to operate and replace. The punch stroke (sugar weight) is adjustable online.

The hopper uses electric heating with an easily adjustable temperature.

Its improved cooling tunnel features the same height, longer length and more accurate temperature control over previous models. The full refrigeration unit is integrated into the refrigerated cooler.

The unique demolding device features a tank chain structure and is equipped with a rotating brush to ensure a full candy demolding process.

Its PVC cooling conveyor belt is manufactured using the latest technology. It features a smooth appearance and is easy to clean and maintain, ensuring a long service life.

The production line can be customized to fit your site conditions.

Model:ZY600

Capacity:600kg/h

Candy weight:According to the size of candy

Depositing Speed:25-55n/min

Working condition:20-25,C temperature humidity 55%

Electric power needed:36kw/380v

Total Length:22m

Weight of machine:6000kg

Flow of gummy making machine

Jacket cooker-Mix tank-Lobe pump-Storage tank-Depositor-Cooling tunnel-Oil spray-bagging machine

continuous cooking system for both pectin/gelatin gummy

-2x 500L Jacket heated Pectin and sugar dissolving tank with High shear mixer and variable speed drive.

-1x 500L cooling and heating gelatin tank with high shear mixer, variable speed drive and Sweep mixing with scrapers

– Heated transfer pump with variable speed control

– Hot water recirculation system including Jacket transfer pipes, water tank with heaters and recirculation pump

– 1x600L Jacket heated storage tank with sweep mixing with scrapers and variable speed drive

-Integrated electrical cabinet including control of main power of each cook and control of VFD, and Temperature

-Load cell weighing sensors as options

-SS316 Food contact part

Mixers System

-Static and inline mixers for colors, flavors and Acid

Depositing and demolding system

-Servo driven and Siemens PLC control

-Auto mold lubrication system

-Quick release mold set

-hopper heating system

-Dual hopper as options for dual color and central filled gummy

-LED HMI 10′ Siemens Touch Screen

Cooling system

-FDA Approved Non-stick cooling belt

-20HP Air cooling with designed enclosed cooling tunnel

-Electrical cabinet with 0-20C temperature and humidity control

Coating system

-Z type Conveyor from cooling tunnel to coating drum

-Variable Speed control

-Oil, wax and sugar coating available

Model:ZY450Q

Capacity:450kg/h

Candy weight:According to the size of candy

Depositing Speed:25-55n/min

Working condition:20-25,C temperature humidity 55%

Electric power needed:32kw/380v

Total Length:20m

Weight of machine:5000kg

Flow of gummy making machine

Jacket cooker-Mix tank-Lobe pump-Storage tank-Depositor-Cooling tunnel-Oil spray-bagging machine

Advantages of gummy Candy Production Line

Rapid pouring, rapid cooling and fast production

High production precision

Perfect technology, convenient parts replacement, and perfect after-sales system

The product quality is good, which is equivalent to similar products in Europe

Medium gumm production line

The gummy production line can be made of a variety of shapes and colors of gummy candy according to the mold, and developed by advanced production technology. It is an ideal device for the continuous production of advanced colloidal candy.

It can produce high quality monochrome and dual-color sugar; it can also produce high quality, various shape and various color gel jelly by changing the mold or pouring head. Complete the quantitative filling mixing of flavor pigment acid online; highly automated production can not only produce stable quality products.

1.Automatic control for the dissolving temperature, with PLC and touch screen individual control for high automation

2.Storage tank with level sensor to detect the syrup level

3.The dissolving tank bottom equipped with pneumatic valve and tube filter to prevent the syrup stuck the lobe pump

4.The pipes are equipped with filter device

5.This weighing system ensure each batch of the ingredients with the accurate proportion, so that to guarantee the candy quality is the same by each batch.

6.In this step, water, sugar and mixed, glucose and pectin syrup will be weighed.

Gummy production line video

Model:ZY300Q

Capacity:300kg/h

Candy weight:According to the size of candy

Depositing Speed:25-55n/min

Working condition:20-25,C temperature humidity 55%

Electric power needed:26kw/380v

Total Length:20m

Weight of machine:4500kg

Flow of gummy making machine

Jacket cooker-Mix tank-Lobe pump-Storage tank-Depositor-Cooling tunnel-Oil spray-bagging machine

Control system

The gummy making machine has a programmable logic controller (PLC), which is a touch screen. Equipped with LED touch panel for efficient and easy control.

You can customize the corresponding mold according to the shape of the desired gum. You can process different shapes of gum by changing different molds.

Model:ZY150Q

Capacity:150kg/h

Candy weight:According to the size of candy

Depositing Speed:25-55n/min

Working condition:20-25,C temperature humidity 55%

Electric power needed:16kw/380v

Total Length:18m

Weight of machine:3000kg

Flow of gummy making machine

Jacket cooker-Mix tank-Lobe pump-Storage tank-Depositor-Cooling tunnel-Oil spray-bagging machine

characteristic

Automation level, you will realize the reduction of labor cost.

The automatic nature of the machine leads to an increase in output.

Because of the touch screen and PLC control panel for configuration, the monitoring and adjustment of production operation is simpler.

The machine is mainly made of stainless steel, so it is not easy to be polluted.

The man-machine interface on the machine makes it easy to operate.

The maintenance cost is low, and only the moving parts need to be cleaned and lubricated regularly.

Model:ZY150Q

Capacity:80kg/h

Candy weight:According to the size of candy

Depositing Speed:25-55n/min

Working condition:20-25,C temperature humidity 55%

Electric power needed:10kw/380v

Total Length:13m

Weight of machine:2000kg

Flow of gummy making machine

Jacket cooker-Mix tank-Lobe pump-Storage tank-Depositor-Cooling tunnel-Oil spray-bagging machine

1. Automatic control of the dissolution temperature, with PLC and touch screen separately controlled high automation

2. Storage tank with level sensor to detect syrup level

3. The bottom of the dissolving tank is equipped with pneumatic valve and tube filter to prevent the syrup from sticking to the leaf pump

4. It can process candy of various shapes

5. The weighing system ensures that the proportion of ingredients in each batch is accurate to ensure that each batch of candy has the same quality.

6. In this step, water, sugar and mixture, glucose and pectin syrup will be weighed

7. Demoulding is completely clean and sanitary, and the candy is uniform overall

Small scale gummy candy machine

Small scale gummy candy machine are divided into full-automatic small scale gummy making machine and semi-automatic small gummy candy machines. The full-automatic small gummy candy machines can be equipped with automatic feeding system and automatic mold system. The semi-automatic small gummy candy machines need to manually change the mold and demould when pouring.

Small gummy making machine video

Automatic small scale gummy making machine

Motor: servo motor

Material: 304 stainless steel

Power input: 110/220V AC/50-60HZ

Power output: 24V DC/MAX.1.5KW

Maximum temperature: 100 ℃

Application of food, pills, candy, chocolate, etc

Small scale semi-automatic gummy candy machine

Machine Model: GD20

This is initial machine model, driven by cylinder, can only make solid gummy.

Manually change depositing quantity.

Machine Materials: Stainless steel 304.

Depositing nozzles: pure cooper

Electrical components: Siemens - Germany

Cylinder : Airtac - Taiwan,China

Temperature sensors: Omron -Jacky

Voltage :380V 50HZ,3PH

Strike speed :30times/min

Depositing quantity:1-10g

Hopper volume: 23L

Consumption of air 20CBM/min

Power:7.2kw

Dimensions:800*800*1700mm

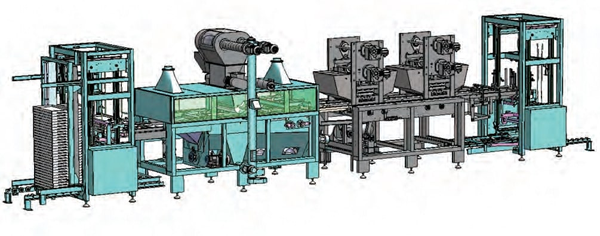

Starch Gummy Candy Production Line

Starch Mogul Line is an advanced fully automatic soft candy production line. High quality, convenient operation, stable operation and high output. The entire production line includes kitchen system, mogul production line, starch conditioning system, starch collection and recycling system, product finishing and supporting systems.

Product Standardization Machine

1.Gummy boiling machine

Capacity 700kg/h

Power 7kw

Water consumption 1800L/h

Steam consumption 600kg/h

Steam pressure 0.7Mpa

Compressed air pressure 0.6Mpa

Size(L*W*H) 2000*1200*2450mm

2.Starch Mogul Line Specification

Capacity 1000kg/h

Power 105kw

Compressed air pressure 0.7-0.8Mpa

Compressed air consumption 300m3 /h

Chilled water consumption 315kg/min

Chilled water temperature 4℃

Starch tray size(L*W*H) 820*400*56mm

Features of Starch Mogul Production Line

With high applicability, it can produce starch soft candy, gelatin, carrageenan, mixed gum and other soft candy products.

Mature pouring and demoulding system provides customers with perfect products

High-end quality, comparable to similar equipment in Europe

Mature processing technology, convenient replacement of spare parts, perfect after-sales service system

The production line can be customized to perfectly suit your operation.

The syrup flow rate is precisely controlled by the frequency conversion control system to ensure stability.

3-Depositor Gummy Candy Starch Mogul Line

the machine features easy operation and steady working. The processing for the whole line includes cooking, deposit- ing(servo central-filled depositing included), finished product transfer!ng, powder disposing and recycling system.

The customer can choose the candy size. Then, we offer our professional layout design for the customer to reach the largest production capacity by approving steady running and stable starch moulds.

This production line is controlled by PLC system with automatic starch molding feeding and unloading.

The candy and the powder are separated automatically. Starch adjusting system covers independent drying and cooling template. They are connected by spiral

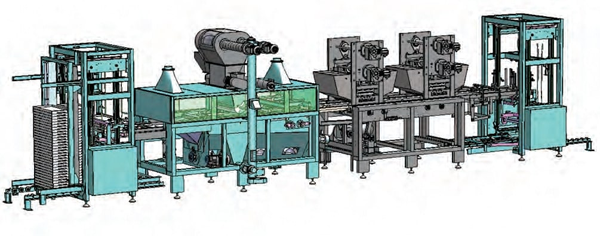

Semi-Automatic Jelly Candy Starch Mogul Line

The Gummy Candy starch mogul line is designed for producing starch Gummy Candy. It is PLC controlled and features a maximum capacity of 400 to 800kg/hour. It uses a servo motor to convey pallets, and features a low start speed, low speed brake, high speed operation, a smooth operation and an excellent work efficiency.

It is suitable for pouring out different shapes of gummy, gel gummy, pectin gummy candy, carragenan gummy candy, all kinds of vitamins gummy candy, functional jelly gummy candy, health gummy candy products, etc

Working principle of gumm making machine

Usually, the supplier will make know-how training for your workers.

Step One: Raw material preparation

According to your formula, prepare all the raw materials before running the gummy bear machine. Make sure all the ingredients in the right quantity.

Step Two: Cooking of the ingredients

Mixing sugar, glucose, water in the dissolving cooker for around 15-20minuites to get the syrup you need, transfer the mixture to the buffer tank.

At the same time, start cooking the next batch.

Step Three: Additities on-line mixing

The mixture flows to an on-line mixer for flavor, color, acid addition, pumping to the depositor hopper. If you have two sets of the mixer, you can be mixed the mixture with two different flavors and colorings.

Step Four: Gummy Candy Formation

In this stage, different shapes and colors gummy will be formed by the depositor machine, filling to the gummy molds, the weight of each gummy will be controlled by PLC.

Prevent the molten candy from sticking to the molding machine

Hold the gummy candies intact during the subsequent stages

Retain moisture from the candies, consequently resulting in the desired texture

Thealso has molding plates in various shapes and sizes to shape the processed batch appropriately.

Step Five: Shaped and cooling

The molds will transfer to the cooling tunnel after full filling with the mixture. they will keep moving in the cooling tunnel for 6-10mins based on your gummy bear recipes. then transferred by a conveyor to sugar coating or oil coating machine. after this stage, storage gummy bears to the drying room for 8-12hours which lets the moisture out before packaging.

Installation of the gummy making machine

We will send engineers to help you install the machine

How to choose the gummy machine and price

You can leave us a message or whatsapp contact us, we will provide you with the candy processing scheme and quotation according to your situation

All rights reserved:Zhi Yan Group Co., Ltd SitemapSitemapCandy making machine candy production line Toffee production line biscuit production line lollipop production line Gummy production line Popping boba production lineManufacturer