![]()

Adr :636 Yunqiao Road, Pudong New Area, Shanghai, China

Phone : +86 18221614363

Email : info@zygroups.com

Tel : +86 18221614363

processing capacity:2-1200kg/h

Application scope:Xylitol gum production line,xylitol bubble gum making machine

Product introduction: Automatic Xylitol chewing gum making machine for xylitol gum can produce xylitol ball gum, square xylitol chewing gum,shaped xylitol bubble gum,filled xylitol gum,xylitol bubble gum and other xylitol,We are professional manufacturers of xylitol chewing gum machines

Automatic Xylitol chewing gum making machine for xylitol gum can produce xylitol ball gum, square xylitol chewing gum,shaped xylitol bubble gum,filled xylitol gum,xylitol bubble gum and other xylitol,We are professional manufacturers of xylitol chewing gum machines

1.Automatic xylitol Gum Production Line

2.xylitol chewing Gum Production Line

3.Center Filled xylitol chewing Gum Production Line

5.xylitol chewing Gum types (candy shapes) and applications

6.xylitol chewing Gum making Machine Working Principle

7.Installation of the xylitol chewing Gum making machines

8.xylitol chewing Gum production line for sales and price

1.Automatic xylitol Gum Production Line

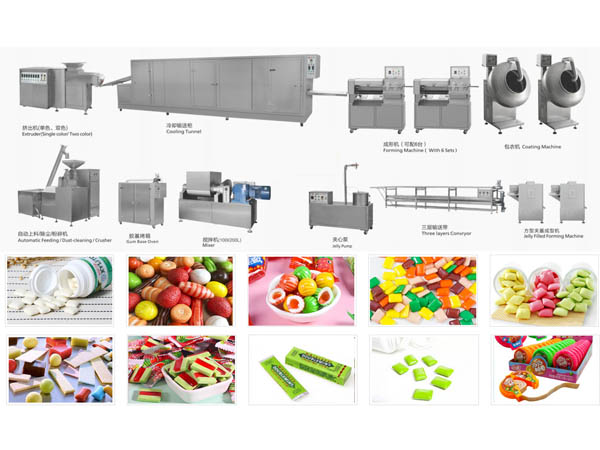

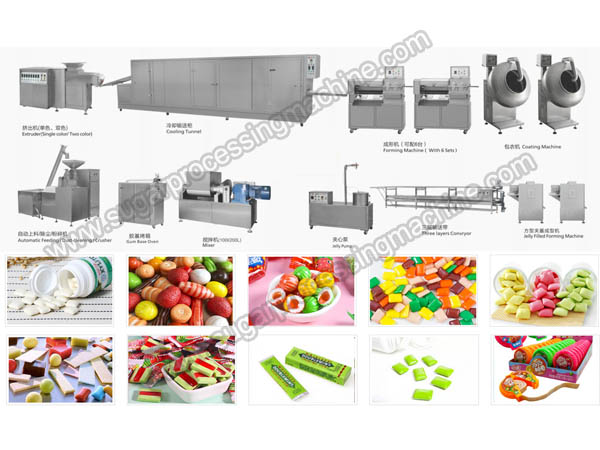

Automatic xylitol Gum Making Machine

This fully-automatic Automatic xylitol Gum Production Line consists of mixer, extruder, six roller tablet, forming machine, cooling tunnel, automatic screening machine, gum base oven and coating machine. It can produce different shapes of xylitol Gum。

Process flow chart of xylitol gum Production Line

mixer-extruder-six roller tablet-forming machine-cooling tunnel-automatic screening machine-gum base oven-coating machine

Main Technical Parameters For Production Line

Capacity:500-600(kg/h)

Adjustable range for candy:Bean Shape:6mm-22mm;Rectangle Shape:6mm-30mm

Dimension:22000x1800x1750mm

Gross power:75kw

Power supply:380V/50HZ 200V-240V/60HZ

Gross weight:11000kg

Technical Parameters For Each Machine

Automatic feeding/Dust Cleaning/ Crushing Machine:Power:17kw,Dimension:3500x1300x2200mm,Weight:400kg

Gum Base oven:Power:18kw,Dimension:1600x600x1700mm,Weight:300kg

Mixer-100L:Power: 20kw,Dimension:2300x860x1550mm,Weight:1500kg

Mixer-200L:Power: 24kw,Dimension:2650x1000x1650mm,Weight:2000kg

Extruder -One Color:Power: 15kw,Dimension:2500x900x1500mm,Weight:1000kg

Extruder -Two Color:Power:22kw,Dimension:2600x1150x1500mm,Weight:2200kg

Six Roller Tablet:Power:5kw,Dimension:5100x950x1880mm,Weight:2000kg

Forming Machine:Power:2.2kw,Dimension:1800x780x1650mm,Weight:800kg

Cooling Tunnel-600 Width:Power:20kw,Dimension:8850x1900x1850mm,Weight:2500kg

Cooling Tunnel-800 Width:Power:22kw,Dimension:8850x2100x1850mm,Weight:2700kg

Automatic Screening Machine:Power:3kw,Dimension:2200x1000x1400mm,Weight:350kg

Coating Machine:Power:2kw,Dimension:1050x1050x1600mm,Weight:350kg

2.xylitol chewing Gum Production Line

xylitol chewing Gum Production Line

xylitol chewing Gum Production Line is composed by mixer, extruder, cooling tunnel/3 layers conveyor, forming machine (6 sets), coating machine, jelly filled forming machine and gum base oven. It can be produced hollow, powder filling or jelly filling xylitol chewing Gum in the shapes of balls, strawberry, oval, column, and so on.

Process flow chart of xylitol chewing Gum Production Line

mixer-extruder-cooling tunnel/3 layers conveyor-forming machine-coating machine-jelly filled forming machine-gum base oven

Main Technical Parameters For Production Line

Capacity:400-650(kg/h)

Diameter of candy:10-25mm

Dimension:15000x4000x1500mm

Gross power:82kw

Power supply:380V

Gross weight:8850kg

Technical Parameters For Each Machine

Automatic feeding/Dust Cleaning/ Crushing Machine:Power:17kw,Dimension:3500x1300x2200mm,Weight:400kg

Gum Base oven:Power:18kw,Dimension:1600x600x1700mm,Weight:300kg

Mixer-100L:Power:20kw,Dimension:2300x860x1550mm,Weight:1500kg

Mixer-200L:Power:24kw,Dimension:2650x1000x1650mm,Weight:2000kg

Extruder-One Color:Power:15kw,Dimension:2500x900x1500mm,Weight:1000kg

Extruder-Two Color:Power:22kw,Dimension:2600x1150x1500mm,Weight:2200kg

Jelly Pump:Power:3kw,Dimension:1600x550x1650mm,Weight:300kg

Cooling Tunnel-600:Power:20kw,Dimension:8850x1900x1850mm,Weight:2500kg

Cooling Tunnel-800:Power:22kw,Dimension:8850x2100x1850mm,Weight:2700kg

Three layers Convryor:Power:2.3kw,Dimension:10500x900x1450mm,Weight:300kg

Forming Machine:Power:1.5kw,Dimension:1320x950x1600mm,Weight:400kg

Jelly Filled Forming Machine:Power:2.2kw,Dimension:1200x1200x1300mm,Weight:650kg

Coating machine:Power:2kw,Dimension:1050x1050x1600mm,Weight:350kg

3.Center Filled xylitol chewing Gum Production Line

Center Filled xylitol chewing Gum Production Line

Parameters

Capacity:250 ~ 300kg/h

Total power:24kW

Shell dimension:11.2mx 1.5m x 2m

Total weight:7800kg

Center Filled xylitol chewing Gum Production Line is designed for producing central filled xylitol chewing Gum or center filled xylitol Gum as per the design of the xylitol chewing Gum shape. Center Filled xylitol chewing Gum Production Line has an excellent reliable perfor mance and changeable xylitol chewing Gum style, such as xylitol chewing Gum and xylitol Gum, chewy candy etc.

Xylitol gum production line is mainly composed of glue-based oven, blender, extrusion molding machine (extruder, conveying powder machine, leather machine, powder sucking machine, forming machine), icing machine, etc. The production line is automatically controlled by PLC program, sanitary design, powerful, compact and reasonable structure, beautiful appearance. It is the ideal equipment for large and medium-sized food enterprises to produce chewing gum (xylitol gum).

characteristic

Vacuum boiling sugar and inflatable stirring automatic control alternately;

Unique design of inflatable stirring device to ensure the quality of products;

Production capacity up to 300kg per hour;

Synchronous automatic control of sandwich/extrusion/strip;

Chain forming can complete the production of different shapes of xylitol chewing Gum online;

Can produce ordinary xylitol chewing Gum, xylitol Gum, toffee, etc.

Extruder(single color)

The extruder is used to extrude xylitol chewing Gum. It is equipped with a stainless-steel hopper with an extrusion head made of a high hardness steel coated in polytetrafluoroethylene. The extrusion head maintains its temperature via hot water to ensure the gum base remains warm and soft to avoid cracking or breaking.

Power:15kw

Dimensions:2500*900*1500mm

Machine weight:1000kg

Extruder(two color)

Power:22kw

Machine weight:2200kg

Forming machine

Power:1.5kw

Dimensions:1320*950*1600mm

Machine weight:400kg

The forming machine produces xylitol chewing Gum in a variety of sizes according to customer requirements.

Coating machine

Power:2.2kw

Dimensions:1600*730*1450mm

Machine weight:350kg

This machine is used for polishing the candy surface.

Cooling Tunnel

Cooling Tunnel(600)

Power:20kw

Dimensions:8850*1900*1850mm

Machine weight:2500kg

Cooling Tunnel(800)

Power:22kw

Dimensions:8850*2100*1850mm

Machine weight:2700kg

Mixer

This machine is designed to mix xylitol chewing Gum raw materials and features a high efficiency.

Mixer(100)

Power:20kw

Dimensions:2300*860*1550mm

Machine weight:1500kg

Mixer(200)

Power:24kw

Dimensions:2650*1000*1650mm

Machine weight:2000kg

Gum base oven

Power:18kw

Dimensions:1600*600*1700mm

Machine weight:300kg

Jelly Filled Forming Machine

Power:2.2kw

Dimensions:1200*1200*1300mm

Machine weight:650kg

5.xylitol chewing Gum types (candy shapes) and applications

Can make different shapes of xylitol chewing Gum: ball xylitol chewing Gum, square xylitol chewing Gum, shaped xylitol chewing Gum, sandwich xylitol chewing Gum and so on

6.xylitol chewing Gum making Machine Working Principle

xylitol chewing Gum production line by blender, extruder, molding machine, cooling machine and icing machine. It is the ideal equipment for producing xylitol chewing Gum of various shapes, such as ball type, watermelon type, oval shape, dinosaur egg shape, wine pot type. The output of the equipment is beautiful in shape, stable in machine performance, simple in operation and maintenance.

The line can also produce various shapes of milk candy, single or two color xylitol chewing Gum. The production line has high efficiency, good sanitary conditions and stable operation performance, is the ideal equipment for the production of high-end candy.

Main features:

-using PLC control technology, high degree of automation;

-the use of two extrusion, make the xylitol chewing Gum tissue fine, taste better;

-the use of vacuum negative pressure suction powder, production environment;

-the horizontal roller anti-dandruff machine xylitol chewing Gum smooth without burr.

7.Installation of the xylitol chewing Gum making machines

We will send engineers to help you install the machine

8.xylitol chewing Gum production line for sales and prices?

You can leave us a message or contact us on whatsapp, and we will provide you with the plan and quotation of your xylitol gum processing machine at the latest time according to your situation

Automatic xylitol chewing gum making machine video

All rights reserved:Zhi Yan Group Co., Ltd SitemapSitemapCandy making machine candy production line Toffee production line biscuit production line lollipop production line Gummy production line Popping boba production lineManufacturer