![]()

Adr :636 Yunqiao Road, Pudong New Area, Shanghai, China

Phone : +86 18221614363

Email : info@zygroups.com

Tel : +86 18221614363

processing capacity:2-1200T/H

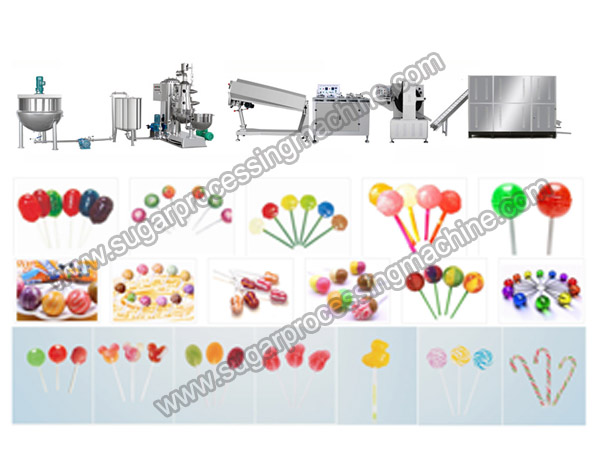

Application scope:Lollipop processing machine can make round,spherical,shaped,single harvest,colorful lollipops

Product introduction: Lollipop production line includes depositing lollipop production line and die formed lollipop making equipment. Automatic lollipop making machine can make round, spherical, shaped, single harvest and colorful lollipop.

Lollipop candy making machine is divided into Die-Formed lollipop Production Line and Depositing lollipop Production Line

1.Die-Formed lollipop Production Line

Automatic Die-Formed lollipop Production Line

Irregular-shaped lollipop production line

Flat lollipop/cane candy production line

2.Depositing lollipop Production Line

Automatic Depositing lollipop Production Line

Servo Driven Lollipop Depositing Line

Full Automatic Servo Control Flat Lollipop Depositing Line

Full Automatic Servo Driven Galaxy Lollipop Depositing Line

3.lollipop candy types (candy shapes) and applications

4.lollipop candy making Machine Working Principle

5.Installation of the lollipop making machines

6.lollipop Candy production line for sales and price

1.Die-formed lollipop Candy Production Line

This line can produce all kinds of die-formed lollipop candy.

Automatic Die-Formed lollipop Production Line

TECHNICAL PARAMETERS

Output:150~1200kg/h

Speed:120-1800Pc/min

Maximum candy weight:16g

Minimum candy weight:2g

Steam Pressure:0.5-0.8Mpa

Steam Consumption:150~600kg/h

Working environment requirements:Room temperature:20-25℃, Humidify:55%

Power:12-60KW/380V

Length:16m-26

Weight:4000kg-11000kg

The die-formed lollipop production line produces lollipop in a variety of shapes through the use of different molds. It is ideal for candy factories planning to mass produce different lollipop candy shapes and features a maximum capacity of 50-1200kg.hour. die-formed lollipop making machine is equipped with an electric heating cooker to ensure an even PLC controlled heating time and temperature, ensuring the lollipop is transparent and features a good taste. This advanced lollipop making equipment effectively reduces material waste. Backed by extensive experience, not only do we offer customized die-formed lollipop production lines, but we also offer the matched molds.

Flowchat of Automatic Die-Formed lollipop Production Line

Sugar dissolving cooker-Liquid glucose storage-Continuous vacuum cooker-Cold table-Batch roller-Rope sizer-Die forming machine-Shaking distribution conveyor-Refrigerated cooler

Machine characteristics

The heating time, heating temperature, depositing time and depositing speed are all computer controlled.

The production line is equipped with a 10.7-inch touch screen for an easy and clear display of different parameters, including the flow chart, part status, temperature, depositing speed and other parameters.

Syrup flow is precisely controlled via a frequency control system to ensure a stable sugar paste quality.

By changing molds and device components, this production line is used in the production of suckers in a variety of shapes, including spherical, flat, and 3D.

It is easy to operate and maintain.

The production line can be customized to fit your site conditions.

Technological process of Ball lollipop production line

Sugar melting cooker-Storage tank-Vacuum sugar cooking machine-Cooling table-Batch roller-Rope sizer-Ball lollipop forming machine-Cooling cabinet-packaging machine

Irregular-shaped lollipop production line

Technological process of Irregular-shaped lollipop production line

Sugar melting cooker-Storage tank-Vacuum sugar cooking machine-Cooling table-Batch roller-Rope sizer-Irregular-shaped lollipop forming machine-Conveyor-packaging machine

Flat lollipop/cane candy production line

Technological process of Irregular-shaped lollipop production line

Sugar melting cooker-Storage tank-Vacuum sugar cooking machine-Cooling table-Batch roller-Rope sizer-Rubbing machine-shaped lollipop forming machine-Cane candy forming machine-Conveyor-packaging machine

Main component equipment

Vacuum sugar cooking machine

It features automatic temperature control, high output, time-saving, short cooking time, and can manufacture the syrup with high transparency.

①.Sugar melting cooker

Batch size(L):300

Weight(kg):280

Dimension(mm):1100*1100*1700

②.Storage tank

Batch size(L):300

Weight(kg):220

Dimension(mm):740*740*1250

③.Technical parameters

Production capacity(kg/h):350-400

Heating area(m³):2.45

Steam pressure(MPa):0.7-1.0

Steam consumption(kg/h):约about100

Syrup temperature before entering(°C):110-115

Temperature after discharging(°C):135-145

Power-Fixed displacement pump(kw):0.75

Power-Vacuum pump(kw):5.5

Dimension(mm):1900*1700*2300

Machine weight(kg):800

Heat preservation batch roller and rope sizer

Purpose:It is suitable for heat insulation and pulling of sugar pastes.

Feature:It has such features as simple operation, labor saving and high efficiency.

Technical parameters

Batch roller maximum capacity(m³):0.20

Running speed(m/min):≤40

Total power(kw):7

Weight(kg):850

Dimension(mm):(Four-wheel):4270*890*1700

Dimension(mm):(Five-wheel):4525*890*1700

Irregular-shaped lollipop forming machine

Purpose:It is suitable for producing irregular-shaped lollipops, such as: oblate, oval, big foot and cartoon irregular-shaped lollipops (shapes varying according to customer requirements).

Feature:It adopts top pressing type punching and forming, with simple operation, high efficiency and manpower saving.

Technical parameters

Production capacity: 150-250pcs/min

Lollipop weight: 10-20g/piece

Total power: 2.5kw

Weight: 1550kg

Dimension: 1950x860x 1640mm

Extruding machine

Technical parameters

Production capacity(kg/h):200-300

Total power(kw):11

Dimension(mm):1380x500x1480

Weight(kg):1100

Lollipop Cooling Machine

lollipop Cooler Is High Efficiency And Energy Saving Cooling Equipment Which Is Special Designed To Match High Production Of Forming Lollipop Such As Die Forming Lollipop.This Cooling System Provides Rapid Cooling For Die Forming Lollipop With Less Noise And Good Effect. It Adopts Wiggly Vibration Plate By Cam And Rocker To Cool Down And Transfer Lollipop. During Cooling And Transferring, Lollipop Cool Down Equably And Won't Be Cracking.meanwhile, Wiggly Vibration Plate Avoids Lollipop Lapping And Conglomeration On Transfer Plate Effectively, Unique Full Close Design And Super Silence Effect Is Fully Meet Environment Protection Requiremeats. It Is Optimum Die Forming Lollipop Cooling Equipment.

Automatic ball lollipop twist packaging machine

Purpose

Suitable for ball lollipop twist packaging.

Feature

It is suitable for twist packaging of ball lollipops.

Provided with the automatic lollipop arranging and feeding device, it has such features as novel structure, beautiful style, low noise, stable running and convenient maintenance.

The AC motor with frequency converter realizes stepless variable speed control.

It adopts automatic computer control and photoelectric color code tracking.

It adopts the internationally advanced photoelectric sensor for detection and two-way tracking, with such functions as fast tracking, accurate patterns and being able to effectively eliminate packaging errors.

The parts that contact food are made of stainless steel, meeting sanitary requirements with easy cleaning.

Irregular lollipop twist packing machine

Purpose and features

With the numerical control display screen and stable control system, operation is easy, you may adjust the parameters when machine is working. With electronic film-drawing system, filmdrawing is more accurate and smooth. With independent temperature control system, the machine finishes packing procedures automatically. Parts that direct contact with the lollipop is made of soft materials in case of bruising.

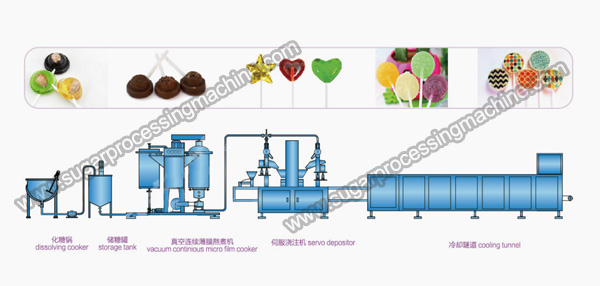

2.Automatic Lollipop Depositing Line

Automatic Depositing lollipop Production Line

TECHNICAL DATA:

Capacity(10g candy):150kg-1200/h

Power consumption:16kw-58kw

Compressed air consumption:0.5m3/min

Compressed air pressure:0.4-0.6Mpa

Steam consumption:250-1200kg/h

Steam pressure:0.6-0.8Mpa

Water consumption:2200L/h

Total Length:17-50mm

Weight:4000-12000kgs

The lollipop depositing production line produces variety of color lollipops, as well as ball and double-ball lollipops in a layered or striped style. Compared to the die-formed lollipop production line, this equipment set features a smoother product surface and smaller labor costs. It is ideal for lollipop mass production.

Automatic lollipop depositing production line is mainly used for lollipop making. It integrates mechanical, electric, compressed air, and automatic control. feature is its high capacity, high quality, various product design, easy operation, reliable

structure design, and high automatic grade. It can not only produce single color lollipop, double colors lollipop, center filled lollipop, but also double balls lollipop product by depositing system increased.

TECHNICAL DATA:

Capacity(10g candy):150kg-1200/h

Power consumption:16kw-58kw

Compressed air consumption:0.5m3/min

Compressed air pressure:0.4-0.6Mpa

Steam consumption:250-1200kg/h

Steam pressure:0.6-0.8Mpa

Water consumption:2200L/h

Total Length:17-50mm

Weight:4000-12000kgs

lollipops manufactured using this line are extremely popular due to their clear strip, precise amount and position of filled materials. The entire production line is manufactured to meet GMP and food safety standards, ensuring it is easier for your company to pass GMP, QS and HACCP certifications.

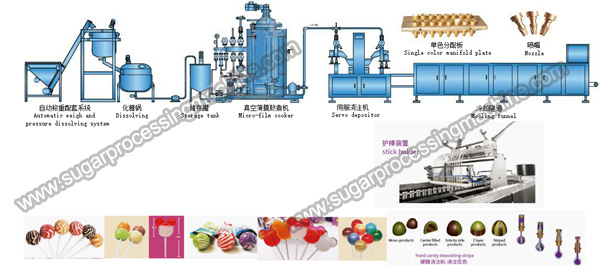

The production line is composed of sugar dissolving cooker, storage tank, candy vacuum micro-film cooker, depositing machine, molds and cooling tunnel. The production line can produce double-color striped , double-color double-layer,Lollipop candies can be produ customers.

The Lollipop production line adopts PLC to control candy vacuum cooking, conveying and depositing procedures. Rationed essence, pigment and acid solution can be completed on The machine is equipped with the automatic stick placing device with good stability and reliability. The whole production line adopts sanitary design with compact structure and reliable performance

Features

The heating time, heating temperature, depositing time and depositing speed are all computer controlled.

The production line is equipped with a 10.7-inch touch screen for an easy and clear display of different parameters, including the flow chart, part status, temperature, depositing speed and other parameters.

Syrup flow is precisely controlled via a frequency control system to ensure a stable sugar paste quality.

By changing molds and device components, this production line is used in the production of suckers in a variety of shapes, including spherical, flat, and 3D.

A chocolate depositing system is optional for use in the production of chocolate filled suckers.

Simply change a few parts and molds, and the production line becomes suitable for the production of hard candy.

The production line can be customized to fit your site conditions.

Process flow of Automatic Lollipop depositing production line

Servo Driven Lollipop Depositing Line (With PLC Controlled)

This lollipop depositing line is designed base on the hard candy depositing line. With more than 20 years candy depositor fabricating experience,the 4th generation lollipop depositing line is developed base on the 3rd generation machine.it is an advanced equipment which can continuously produce various kinds of lollipop under a strict sanitary condition.

The whole line is produced according to the GMP stand a rd of food machinery; it is not only an ideal equipment which can produce out good quality products with the saving of both the manpower and the space occupied, but also help the candy manufacturer pass the GMP, HACCP, QS authentication easily.

Model:ZY1200B-S-Automatic depositing lollipop making machine

Capacity:1200kg/h

Candy weight:According to the size of candy

Depositing Speed:30-60n/min

Steam requirement:1200kg/h,0.5-0.8MPa

Compressed air requirement:0.6m³/min,0.4-0.6MPa

Working condition:Temperature 20-25°C;Humidity 45-55%

Electric power needed:56kw/380v

Total Length:40m

Weight of machine:12000kg

Model:ZY600B-S-Automatic depositing lollipop making machine

Capacity:600kg/h

Candy weight:According to the size of candy

Depositing Speed:25-35n/min

Steam requirement:500kg/h,0.5-0.8MPa

Compressed air requirement:0.3m³/min,0.4-0.6MPa

Working condition:Temperature 20-25°C;Humidity 45-55%

Electric power needed:38kw/380v

Total Length:22m

Weight of machine:7000kg

Model:ZY450B-S-Automatic depositing lollipop making machine

Capacity:450kg/h

Candy weight:According to the size of candy

Depositing Speed:25-35n/min

Steam requirement:400kg/h,0.5-0.8MPa

Compressed air requirement:0.25m³/min,0.4-0.6MPa

Working condition:Temperature 20-25°C;Humidity 45-55%

Electric power needed:34kw/380v

Total Length:19m

Weight of machine:6000kg

Model:ZY300B-S-Automatic depositing lollipop making machine

Capacity:300kg/h

Candy weight:According to the size of candy

Depositing Speed:25-35n/min

Steam requirement:300kg/h,0.5-0.8MPa

Compressed air requirement:0.2m³/min,0.4-0.6MPa

Working condition:Temperature 20-25°C;Humidity 45-55%

Electric power needed:27kw/380v

Total Length:19m

Weight of machine:5000kg

Model:ZY150B-S-Automatic depositing lollipop making machine

Capacity:150kg/h

Candy weight:According to the size of candy

Depositing Speed:25-35n/min

Steam requirement:250kg/h,0.5-0.8MPa

Compressed air requirement:0.2m³/min,0.4-0.6MPa

Working condition:Temperature 20-25°C;Humidity 45-55%

Electric power needed:18kw/380v

Total Length:17m

Weight of machine:4000kg

Full Automatic Servo Driven Hard Candy Depositing Line

Full Automatic Servo Driven Hard Candy Depositing Line flow process

Automatic weight and pressure dissolving system->Dissolving cooker->Storage tank -> Micro-film cooker-> Servo depositor -> Cooling tunnel — De-moulding — Conveying-> Packing

Full Automatic Servo Control Flat Lollipop Depositing Line

Full Automatic Servo Control Flat Lollipop Depositing Line

Model:ZY150P-Full Automatic Servo Control Flat Lollipop Depositing Line

Capacity:150kg/h

Lollipop weight:According to size of the lollipop

Depositing Speed:25 ~ 55n/min

Steam requirement:250kg/h, 0.5~0.8MPa

Compressed air requirement:0.2m3/min, 0.4-0.6MPa

Electric power needed:18kW/380V

Total Length:17m

Weight of machine:4000kg

Model:ZY300P-Full Automatic Servo Control Flat Lollipop Depositing Line

Capacity:300kg/h

Lollipop weight:According to size of the lollipop

Depositing Speed:25 ~ 55n/min

Steam requirement:300kg/h, 0.5~0.8MPa

Compressed air requirement:0.3m3/min, 0.4-0.6MPa

Electric power needed:27kW/380V

Total Length:19m

Weight of machine:5000kg

Full Automatic Servo Driven Galaxy Lollipop Depositing Line

Full Automatic Servo Driven Galaxy Lollipop Depositing Line(Ring Lollipop Production Line)

Model:ZY150H

Production capacity:120-750kg/h

Weight of candy:5-40g/ 粒(grain)

Air consumption:0.3m3/min,0.4-0.6mpa

Steam consumption:450kg/h

Demensions:21*0.9*2.6m

Weight of machine:4000kg

ZY150H 3D lollipop production line is one kind of art candy production equipment which suit for the large grain of candy shape. This machine not ony producting semi-solid and full solid lollipop but also producing normal lollipop.

Can producing single color, double color double flavour lollipop, stripe lollipop. This machine with machanic. Elctric , pneumatic and cancel the cam system, construction tightly,designing resonable.With high automaticly, it is a perfect lollipop production equipment.

Main machine

Vacuum microfilm cooker

It features an automatic temperature control and a high output, ensuring the short cooking period saves time without sacrificing syrup transparency.

Mold

ball lollipop,double-ball lollipop and flat lollipop

Through the use of different molds, this production line manufactures different suckers, including ball suckers, double-ball suckers, and flat suckers. We will design molds according to customer needs.

Depositing machine

The depositing machine is composed of the depositing head, mold, and refrigerated cooler. The depositing head is equipped with double hopper and by replacing the stamping board and nozzle, this equipment is used for the production of filled suckers and two-color suckers. It uses PLC to control different parameters, such as temperature and depositing speed. These parameters are easily set and displayed on the touch screen. Syrup flow is also precisely controlled using a frequency control system to ensure sugar paste quality.

Chocolate center filling device

This device is designed for manufacturing chocolate filled suckers. The double-layered storage tank prevents chocolate solidification.

Confectionery packaging system

Candy is a kind of candy that has low water content and absorbs water vapor easily. After gyroscopic product hair closing, return sand. Thereby reducing or losing the value of the commodity. Therefore, packaging for candy is an indispensable means of protection, the role of packaging is to prevent or delay the phenomenon of qualitative change. The reasonable method is to give boiled candy sealed packaging, when the hard candy is in a state of complete isolation from the outside air, although after several years of storage, it is not easy to detect the change of quality.

3.lollipop candy types (candy shapes) and applications

Suitable for pouring and stamping out different shapes of lollipops

4.lollipop candy making Machine Working Principle

Lollipop Depositing molding: conveyor belt, model plate, sugar nozzle, sugar pump, storage tank, cooling device. Casting mold molding can produce lollipop, its wide range of adaptation, the need for roughly the same equipment. When the boiled sugar paste is still in the active state, the liquid sugar paste is injected into the continuous running model plate, and then it is rapidly cooled and shaped, and then separated from the model plate, and then sent to the packaging machine with the conveyor belt for packaging.

Depositing Lollipop Production Line Video

Die-Formed lollipop forming: When the sugar billet is cooled to the appropriate temperature, it can be stamping forming. If the temperature is too high, the sugar body is too soft, it is difficult to form, even if the molding sugar block is easy to stick or deformation, such as the temperature is too low, the sugar billet is too hard, the sugar granules formed out, easy to produce hair darkening and missing edge broken Angle. The appropriate temperature for stamping forming is 80-70℃, when the sugar billet has the most ideal plasticity, stamping forming is to use the characteristics of the sugar billet at this temperature, with the drawing machine or artificial sugar billet stretching into strips, into the forming machine stamping forming.

Die-Formed Lollipop Production Line Video

5.Installation of the lollipop making machines

We will send engineers to help you install the machine

6. lollipop Candy production line for sales and price

You can leave us a message or contact us on whatsapp, and We will provide you with the best solution and quotation for your candy processing machine according to your situation

All rights reserved:Zhi Yan Group Co., Ltd SitemapSitemapCandy making machine candy production line Toffee production line biscuit production line lollipop production line Gummy production line Popping boba production lineManufacturer