![]()

Adr :636 Yunqiao Road, Pudong New Area, Shanghai, China

Phone : +86 18221614363

Email : info@zygroups.com

Tel : +86 18221614363

processing capacity:2-1200T/H

Application scope:Make toffee,peanut toffee candy,chocolate toffee,fruity toffee and more

Product introduction: Automatic toffee production line includes dopositing toffee making machine,die formed toffee making equipment,extrusion toffee candy production line,Make toffee,peanut toffee candy,chocolate toffee,fruity toffee and more taffy candy.

Toffee production line includes casting toffee production line, stamping toffee production line, extrusion toffee candy production line

1.Automatic Depositing Toffee Candy production Line;

Model:ZY600T-Depositing Toffee production Line

Model:ZY450T-Depositing Toffee production Line

Model:ZY300T-Depositing Toffee making machine

Model:ZY150T-Depositing Toffee making machine

2.Die-formed Toffee Production Line

Fully automatic toffee production line

Automatic Central-filled toffee Production Line;

Cylindrical,ball and craft toffee making machine

3.Extruding forming Toffee candy production line

Model:ZY-300E-Extruding Toffee making machine

Model:ZY-600E-Extruding Toffee production line

4.block-shaped toffee production line

5.Toffee Chewing Candy Production Line

6.Toffee candy types (candy shapes) and applications

7.toffee candy making Machine Working Principle

8.Installation of the toffee candy making machines

9.Toffee Candy production line for sales and price

1.Automatic Depositing Toffee Candy production Line

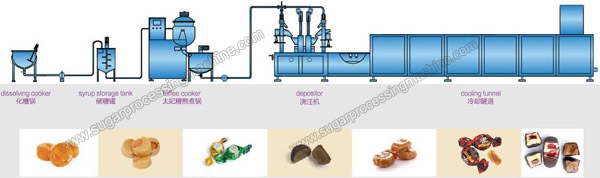

Toffee candy depositing line is an advanced and continuous plant for making different types of toffee candy. It is an ideal equipment which can produce out good quality products with the saving of both the manpower and the space occu- pied.this depositing line consists of jacket dissolving cooker, gear pump, storage tank, special toffee cooker,discharging pump, color & flavor dosing system, color & flavor mixer, depositor, cooling tunnel, electric control cabinet, etc.

Flow chart of Automatic Depositing Toffee Candy production Line

Dissolving cooker-Syrup storage tank- Toffee cooker-Depositor-Cooling tunnel

Main equipment

Toffee cooking machine

The toffee cooking machine is designed to cook a variety of candies, including toffee, eclairs, and caramel. Candy is heated via a steam stirring process to effectively prevent charring.

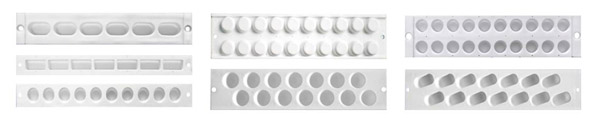

Mold

The production line manufactures candies in different shapes using different molds. We will design molds according to customer needs.

Depositing machine

The depositing machine is composed of depositing head, mold, and refrigerated cooler with the depositing head equipped with a double hopper. By replacing the stamping board and nozzle, this equipment is used to manufacture filled toffee candies. Temperature, depositing speed and other parameters are PLC controlled, with parameters easily displayed and set on the touchscreen. Syrup flow is precisely controlled using the frequency control system to ensure a stable sugar paste quality.

Automatic Depositing Toffee Candy Production Line(Plc Controlled)

Toffee Candy Depositing Line

Toffee candy depositing line is an advanced and continuous plant for making different types of toffee candy. It is an ideal equipment which can produce out good quality products with the saving of both the manpower and the space occu- pied.this depositing line consists of jacket dissolving cooker, gear pump, storage tank, special toffee cooker,discharging pump, color & flavor dosing system, color & flavor mixer, depositor, cooling tunnel, electric control cabinet, etc.

Flow chart of Toffee Candy Depositing Line

Dissolving cooker-Syrup storage tank- Toffee cooker-Depositor-Cooling tunnel

Features

The heating time, heating temperature, depositing time and depositing speed are all Mitsubishi PLC controlled.

The production line is equipped with a 10.7-inch touch screen for display of different parameters, including a flow chart, production line section status, temperature, and depositing speed. It is easy to use.

The syrup flow is precisely controlled via a frequency control system that ensures a stable sugar paste quality.

This equipment will add and mix food colors, food flavors, and acid solutions in an online process.

A chocolate center filing device is optional for the production of chocolate filled toffee.

With the use of different molds, toffee candies in different shapes are manufactured.

The production line is customizable to fit unique customer factory conditions.

Model:ZY600T-Depositing Toffee production Line

Capacity:600kg/h

Candy weight:According to the size of candy

Working condition:temperature 20 - 25 -C humidity 45%

Depositing Speed:25- 55n/min

Electric power needed:38kW/380V

Total Length:22m

Weight of machine:6500kg

Model:ZY450T-Depositing Toffee production Line

Capacity:450kg/h

Candy weight:According to the size of candy

Working condition:temperature 20 - 25 -C humidity 45%

Depositing Speed:25- 55n/min

Electric power needed:34kW/380V

Total Length:20m

Weight of machine:5500kg

Model:ZY300T-Depositing Toffee making machine

Capacity:300kg/h

Candy weight:According to the size of candy

Working condition:temperature 20 - 25 -C humidity 45%

Depositing Speed:25- 55n/min

Electric power needed:27kW/380V

Total Length:20m

Weight of machine:4500kg

Model:ZY150T-Depositing Toffee making machine

Capacity:150kg/h

Candy weight:According to the size of candy

Working condition:temperature 20 - 25 -C humidity 45%

Depositing Speed:25- 55n/min

Electric power needed:18kW/380V

Total Length:18m

Weight of machine:3500kg

2.Die-formed Toffee Production Line

Toffee die forming candy production line

Features of Toffee Candy Die Forming Production Line

The chain punching speed is fast, the product quality is good, and the sandwich content can reach more than 20%

Continuous cooling drum with intermittent cooking machine, cooking pressure up to 0.8Mpa

Change the chain stamping die without pressure for five minutes

The output is up to 800kg/h, which can be used with different cooking equipment to produce various stamping products

The syrup flow rate is precisely controlled by the frequency conversion control system to ensure stability.

Mature processing technology, convenient replacement of spare parts, perfect after-sales service system

The production line can be customized to perfectly suit your operation.

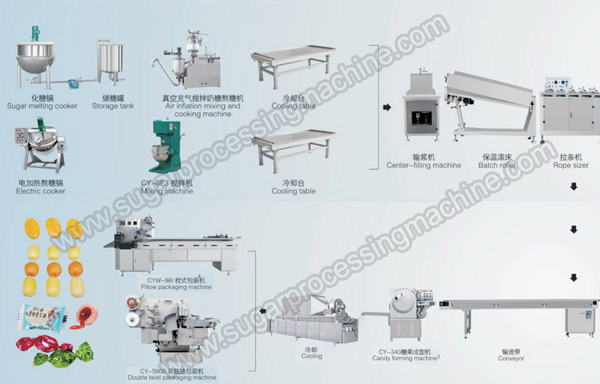

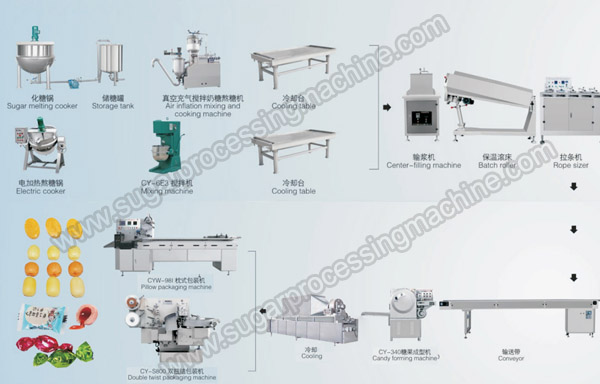

Technological process of Filled/unfilled toffee candy production line

Sugar melting cooker(Electric cooker)-Storage tank-Air inflation mixing and cooking machine(mixing machine)-Cooling table-Center filling machine-Batch roller-Rope sizer-Conveyor-Candy forming machine-Cooling sifter-packaging machine

Main component equipment

Air inflation mixing and cooking machine

Purpose and features:

Made of stainless steel, the unit realizes heating, concentration, rinsing, mixing and blending of traditional aerated candies through reasonable mechanical, electrical, pneumatic and instrumental configuration. It is a key machine for boiling of aerated candies. It is provided with computer PLC automatic control device and touch screen operation. The vacuum boiling, aerating and mixing can be carried out automatically and alternately, so as to carry out high aerating or low aerating boiling of syrup. According to the need, it can also be additionally equipped with boiling pot for the addition of condensed milk or other auxiliary materials.

The machine has relatively high control precision, so the syrup boiled by this machine has very good quality. The machine is suitable for aerating boiling of such products as creamy candies, nougats, fruit candies, spun sugar and candy bar core materials.

Technical Parameters:

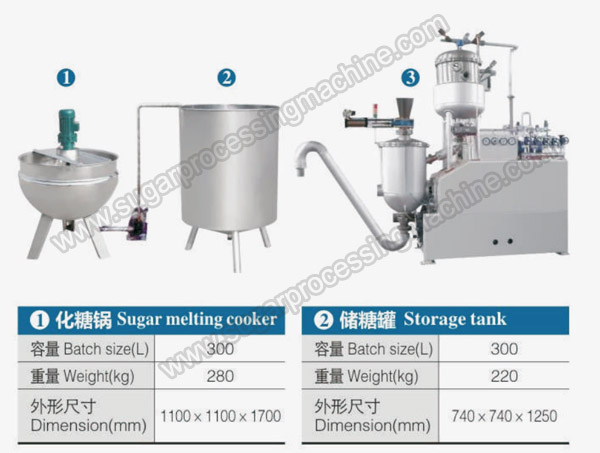

1. Sugar melting cooker

a) Batch size: 300L

b) Weight: 280kg

c) Dimension: 1100*1100*1700mm

2. Storage tank

a) Batch size: 300L

b) Weight: 220kg

c) Dimension: 740*740*1250mm

3. Air inflation mixing and cooking machine

a) Model: CY-300

b) Capacity: 300kg/h

c) Steam pressure: 0.7mpa

d) Steam consumption: 160kg/h

e) Compressed air pressure: 0.6mpa

f) Compressed air consumption: <0.25m³/min

g) Vacuum pressure: -0.06mpa

h) Vacuum pump power: 4kw

i) Main motor power: 17kw

j) Aerating pressure: <0.3mpa

k) Dimension: 2500*1500*3200mm

l) Machine weight: 1500kg

Heat preservation batch roller and rope sizer

Purpose and Features:

It is suitable for heat insulation and pulling of sugar pastes.

It has such features as simple operation, labor saving and high efficiency.

Technical parameter:

1. Batch roller maximum capacity: 0.18m³

2. Running speed: ≤25m/min

3. Total power: 6.3kw

4. Weight: 720kg

5. Dimension: 3700*800*1700mm

Multi function candy forming machine

Purpose

It is suitable for production of hard candies, gaining creamy candies, toffees and filled candies, as well as production of cushions (candy shapes varying according to customer requirements), such as: spherical, oblate, oval and other irregular shapes.

Feature

Punching and forming, stable running, high output

Technical parameters

Production capacity: 250kg/h

Total power: 2.4kw

Weight: 800kg

Dimension: 2000 x 1100 x1300mm

Computer control multifunction pillow packaging machine

It is suitable for granule packaging of regular candies and some irregular-shaped candies, such as: oblong, square, disc-shaped, spherical, cylindrical and oval objects.

Feature

It has such features as variable frequency speed control, photoelectric tracking, simple operation, stable running, high speed and high output.

Purpose

High-speed automatic double twist packaging machine

Feature

-It has such features as simple operation, high efficiency, manpower saving, stable running, low noise and convenient maintenance.

-The core parts use imported novel high precision wheel cam indexing mechanism to make all actions accurate.

-The AC motor with frequency converter realizes stepless variable speed control. With high precision, energy saving and improved service life, dynamic adjustment during the running can be realized.

-It adopts the automatic PLC computer controller and internationally advanced photoelectric sensor for detection and two-way tracking, with such functions as fast tracking, accurate patterns and being able to effectively eliminate packaging errors.

-It is provided with such functions as overload protection, electric leakage protection and alarm in case of no film.

-The parts that contact food are made of stainless steel, with good smoothness and easy cleaning.

-It can use single-layer or double-layer packaging film and can be equipped with automatic feeding hopper.

Automatic ball lollipop twist packaging machine

Feature

It is suitable for twist packaging of ball lollipops.

-Provided with the automatic lollipop arranging and feeding device, it has such features as novel structure, beautiful style, low noise, stable running and convenient maintenance.

-The AC motor with frequency converter realizes stepless variable speed control.

-It adopts automatic computer control and photoelectric color code tracking.

-It adopts the internationally advanced photoelectric sensor for detection and two-way tracking, with such functions as fast tracking, accurate patterns and being able to effectively eliminate packaging errors.

-The parts that contact food are made of stainless steel, meeting sanitary requirements with easy cleaning.

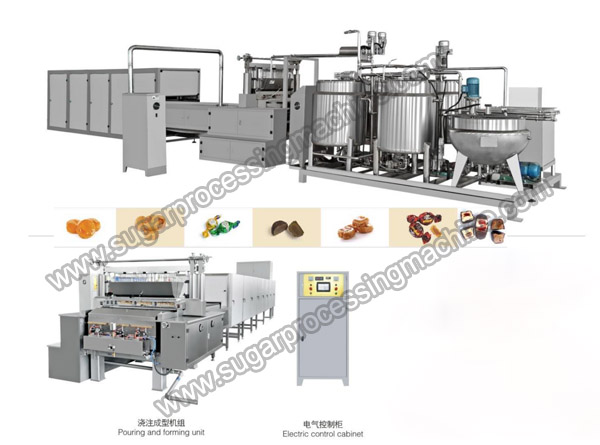

Fully automatic toffee production line

Fully automatic toffee production line

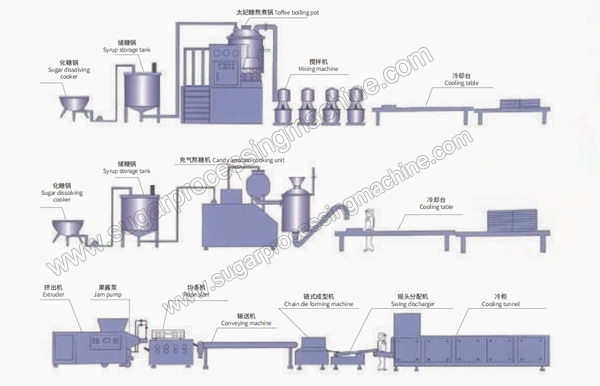

Flow chart of Toffee Candy production Line

1.Sugar melting cooker-Storage tank-Air inflation mixing and cooking machine-cooling table-Center filling machine-Batch roller-Rope sizer-Conveyor-candy forming machine-Cooling-packaging machine

2.Electric cooker-Mixing machine-Cooling table-Center filling machine-Batch roller-Rope sizer-Conveyor-candy forming machine-Cooling-packaging machine

Filled/unfilled toffee production line

Sugar melting cooker-Storage tank-Air inflation mixing and cooking machine-cooling table-Center filling machine-Batch roller-Rope sizer-Conveyor-candy forming machine-Cooling-packaging machine

Cylindrical,ball and craft toffee candy making machine

Technological process of Cylindrical,ball and craft hard candy making machine

Sugar melting cooker-Storage tank-Vacuum sugar cooking machine-Cooling table-Batch roller-Rope sizer-Rotary cutting and forming machine-Cooling sifter-packaging machine

3.Extruding forming Toffee candy production line

ZY300E-Toffee production line

T300 central-filling Chewy candy producing line is one of the main products of ZY Machine. It was introduced and developed according to the demands of the customer that are tasty, functional, colorful, nutritional, etc,. This soft-milk production line can reach to the advanced technology in appearance and performance all over the world.

-Automatic control for alternated process of vacuum cooking and aeration/mixing;

-An unique design of aeration/mixing system guarantees a high quality product;

-The production capacity can reach to 300kg/h;

-Automatic process control synchronized with central-filling/extruding/rope sizing;

-Chain style die-forming for different shapes of candy;

-toffee candy,Soft candy, central-filled soft candy, eclair candy and etc., Can be made.

Main component equipment

Toffee cooking machine

The toffee cooking machine is designed to cook a variety of candies, including toffee, eclairs, and caramel. Candy is heated via a steam stirring process to effectively prevent charring.

Heat preservation batch roller and rope sizer

Purpose and Features:

It is suitable for heat insulation and pulling of sugar pastes.

It has such features as simple operation, labor saving and high efficiency.

Technical parameter:

1. Batch roller maximum capacity: 0.18m³

2. Running speed: ≤25m/min

3. Total power: 6.3kw

4. Weight: 720kg

5. Dimension: 3700*800*1700mm

Extruding machine

Technical parameters

Production capacity(kg/h):200-300

Total power(kw):11

Dimension(mm):1380x500x1480

Weight(kg):1100

Multi function candy forming machine

Purpose

It is suitable for production of hard candies, gaining creamy candies, toffees and filled candies, as well as production of cushions (candy shapes varying according to customer requirements), such as: spherical, oblate, oval and other irregular shapes.

Feature

Punching and forming, stable running, high output

Technical parameters

Production capacity: w250kg/h

Total power: 2.4kw

Weight: 800kg

Dimension: 2000 x 1100 x1300mm

Chain type die forming machine

The forming machine is a new designing of candy forming machine, which is capable of processing toffee candy and chewy candy with or without center filling. This machine is equipped with a central drive, and the forming chain is located

on a carrier driver. The sugar mass chipping and dust can easily be collected under the forming set.The chain forming designing is a special process technology for high speed production development. It is possible to reduce the chain wear percentage by using special designing and material.The chain forming machine features higher capacity of center filled product, and more convenient ejecting of toffee candy by comparing to rotary die forming equipment.

Cooling tunnel

Cooling tunnel is a fast cooling equipment designed to cooperate with high yield candy forming production line such as high-speed stamping forming machine, which can provide ideal cooling distribution for large quantities of candy in the cooling tunnel. Through the circulation cooperation of cooling unit and conveying system, the candy will not be split, deformation, overlap, adhesion and other phenomena in the rapid cooling process. Is ideal for high volume candy cooling equipment.

Model:ZY-300E-Extruding Toffee making machine

Capacity:300kg/h

production speed:1000pcs/min

Candy weight:(Shell) 7g;(central-filling) 2g

Steam Steam pressure:0.2 ~ 0.6 mpa

Steam Consumption:200kgs/h

Total Length:20-25,C/55%

Total Power / Voltage:22kW / 380V

Total Length:17m

Weight of machine:8000kg

Model:ZY-600E-Extruding Toffee production line

Capacity:600kg/h

production speed:1000pcs/min

Candy weight:(Shell) 7g;(central-filling) 2g

Steam Steam pressure:0.2 ~ 0.6 mpa

Steam Consumption:300kgs/h

Total Length:20-25,C/55%

Total Power / Voltage:35kW / 380V

Total Length:19m

Weight of machine:9000kg

4.block-shaped toffee production line

block-shaped toffee production line

Technical parameters

Flattening machine

Total power (kw):1-5

Dimension (mm):1675 x 788 x 1255

Weight (kg):560

Conveying cabinet

Total power (kw):0.75

Dimension (mm):5000 x 788 x 1405

Weight (kg):560

Forming machine

Production capacity (kg/h):200-300

Total power (kw):1.5

Dimension (mm):1850x798x1405

Weight (kg):400

Vibrating sifter

Total power (kw):0.37

Dimension (mm):1210x450x530

Weight (kg):80

Purpose and features

The production line is a new generation of whole-set production equipment of block products manufactured according to the needs of candy manufacturers after absorbing and digesting advanced technologies of machinery from home and abroad. It can be used to produce creamy candies and grain products that take dissolved white sugar as the bond. It has such features as high output, low labor intensity, etc. The production line consists of six-roller roller bed, flattening machine, cooling conveying cabinet, candy bar forming machine and cooling vibrating sieve. The main equipment is provided with variable frequency speed control with proper structure, convenient operation and maintenance. It is an ideal machine for production of candy bars in candy manufacturers.

5.Toffee Chewing Candy Production Line

Toffee Chewing Candy Production Line

This production line is suitable for producing xylitol chewing gum and toffee chewing candy. This fully-automatic production line consists of mixer, extruder, six roller tablet, forming machine, cooling tunnel, automatic screening machine, gum base oven and coating machine. It can produce different shapes of candy, such as square, rectangular, tablet etc. This machine features in reliable performance, simple and flexible operation, high automation. It is one of the good choices for producing xylitol chewing gum and toffee chewing candy.

Process flow chart of Toffee Chewing Candy Production Line

mixer-extruder-six roller tablet-forming machine-cooling tunnel-automatic screening machine-gum base oven-coating machine

Main Technical Parameters For Production Line

Capacity:500-600(kg/h)

Adjustable range for candy:Bean Shape:6mm-22mm;Rectangle Shape:6mm-30mm

Dimension:22000x1800x1750 mm

Gross power:75 kw

Power supply:380V/50HZ 200V-240V/60HZ

Gross weight:11000 kg

Technical Parameters For Each Machine

Automatic feeding/Dust Cleaning/ Crushing Machine:Power:17kw,Dimension:3500x1300x2200 mm,Weight:400 kg

Gum Base oven:Power:18kw,Dimension:1600x600x1700mm,Weight:300kg

Mixer-100L:Power: 20 kw,Dimension:2300x860x1550 mm,Weight:1500 kg

Mixer-200L:Power: 24 kw,Dimension:2650x1000x1650 mm,Weight:2000 kg

Extruder-One Color:Power: 15kw,Dimension:2500x900x1500 mm,Weight:1000 kg

Extruder-Two Color:Power:22 kw,Dimension:2600x1150x1500 mm,Weight:2200 kg

Six Roller Tablet:Power:5 kw,Dimension:5100x950x1880 mm,Weight:2000 kg

Forming Machine:Power:2.2 kw,Dimension:1800x780x1650 mm,Weight:800 kg

Cooling Tunnel-600 Width:Power:20 kw,Dimension:8850x1900x1850 mm,Weight:2500 kg

Cooling Tunnel-800 Width:Power:22 kw,Dimension:8850x2100x1850 mm,Weight:2700 kg

Automatic Screening Machine:Power:3 kw,Dimension:2200x1000x1400 mm,Weight:350 kg

Coating Machine:Power:2 kw,Dimension:1050x1050x1600 mm,Weight:350 kg

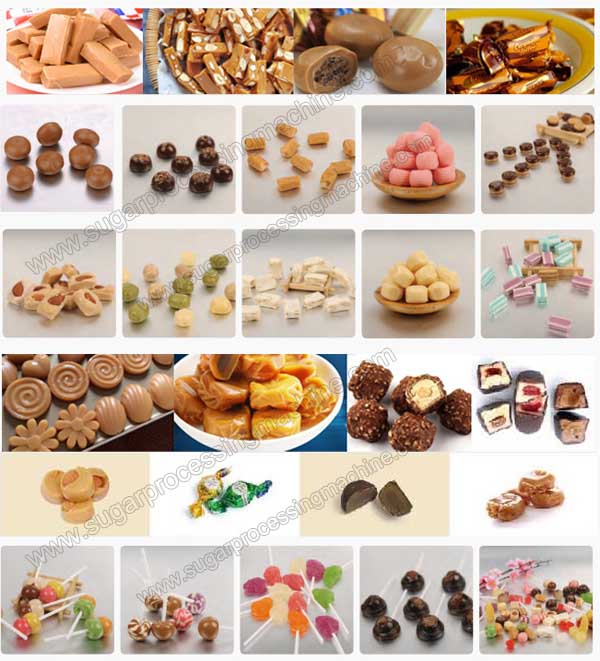

6.Toffee candy types (candy shapes) and applications

Suitable for depositing and die-formed out different shapes of toffee

7.Toffee candy making Machine Working Principle

1. Primary components of toffee pouring machine: conveyor belt, model plate, syrup nozzle, syrup pouring pump, storage tank, cooling device.When the boiled sugar paste is still in the active state, the liquid sugar paste is injected into the continuous running model plate, and then it is rapidly cooled and shaped, and then separated from the model plate, and then sent to the packaging machine with the conveyor belt for packaging.

Automatic Depositing Toffee Candy Production Line Video

2. Continuous stamping of toffee candy forming: when the sugar billet is cooled to the appropriate temperature, it can be pressed forming. If the temperature is too high, the candy body is too soft, it is difficult to form, even if the molding candy block is easy to stick or deformation, such as the temperature is too low, the candy billet is too hard, the candy granules formed out, easy to produce hair darkening and missing edge broken Angle. The appropriate temperature for stamping forming is 80-70℃, when the candy billet has the most ideal plasticity, stamping forming is to use the characteristics of the candy billet at this temperature, with the drawing machine or artificial candy billet stretching into strips, into the forming machine stamping forming.

Die-formed Toffee Production Line Video

3. Extruded toffee candy: This production line is composed of blender, extruded, forming machine, cooling conveyor cabinet, automatic grain separator, glue-based oven and coating machine into an automatic production line, can produce a variety of shapes of toffee candy (such as square, rectangular, sheet shape, etc.). The machine has reliable production, flexible and simple operation, high degree of automation.

Extruding Forming Toffee Candy Production Line Video

8.Installation of the toffee candy making machines

We will send engineers to help you install the machine

9.Toffee Candy production line for sales and price

You can contact us, we will provide you with suitable toffee processing machine scheme and quotation according to your situation

All rights reserved:Zhi Yan Group Co., Ltd SitemapSitemapCandy making machine candy production line Toffee production line biscuit production line lollipop production line Gummy production line Popping boba production lineManufacturer