Adr :636 Yunqiao Road, Pudong New Area, Shanghai, China

Phone : +86 18221614363

Email : zhimachine@foxmail.com

Tel : +86 18221614363

The categories of hard candies include fruit-flavored, cream-flavored, cool-flavored, white-controlling, sand-mixed and roasted-flower hard candies, etc. The requirement for fruit-flavored hard candies is to have the same color, aroma, taste and shape as the fruit.

Hard candy is a candy made by boiling at high temperature. The sugar body is hard and brittle, and belongs to the amorphous non-crystalline structure. It melts slowly in the mouth and is resistant to chewing. The sugar body is transparent, translucent and opaque, and it is also drawn into a mercerized shape. The following introduces 10 main types of hard candy making machine

Hard candy processing equipment

2. Sandwich toffee hard candy production line

3. Fancy candy production line

4. Sandwich hard candy production line

5. Shaped lollipop production line

7. Nougat candy bar production line

8. Chewing gum production equipment

9. Interlayer steam stirring sugar pot

10. Hard candy extrusion molding machine

The hard candy pouring line produces hard candies in various shapes and colors. The machine adopts continuous pouring, fan cooling, automatic demoulding and other devices. It is an integrated automatic hard candy pouring machine, and processes different shapes of hard candies according to the replacement of different pouring molds. Lollipop.

Process flow:

Sugar melting→storage→boiling sugar→casting→cooling→demolding→packing

Scope of application:

It is suitable for casting hard candies of different shapes, spherical lollipops, special-shaped lollipops, special-shaped hard candies, etc.

2. Sandwich toffee hard candy production line

The toffee hard candy production line is composed of a jam conveyor, a powder conveyor, a flattening machine, a cooling conveyor, a switching machine, an insulating roller bed, a stretching machine, a forming machine, a mold, and a vibrating cooling screen. The toffee hard candy production line equipment adopts frequency conversion control to keep the amount of filling in each candy stable. For food contact use stainless steel. The toffee hard candy production line machine can produce jam sandwich

Sugar, powdered (calcium powder, sesame, grape powder, etc.) sandwich candy and other milk candy and heart candy.

Milk candy is divided into: cube milk candy production line, cylindrical milk candy production line, sandwich milk candy production line, most manufacturers of cube milk candy, peanut nougat, sesame candy,

3. Fancy candy production line

Fancy candy making machine and cut flower candy production line, the production capacity of fancy candy production line equipment can reach 1-2 tons/8 hours. Its main machines: 250 Vacuum Sugar Boiling Units, Forming Strand Slicing Units, Automatic Rod Insertion Units and other machines.

Scope of application:

Cylindrical milk candy, fancy candy, chopped flower candy, round candy

Fancy candy production line process:

Sugar, weighing (measurement), melting sugar, vacuum cooking (130~135°C), stirring sugar liquid, candy cooling, candy forming, candy cutting (slicing), candy screening, candy sticking, candy bagging, candy packing box, finished product

4. Sandwich hard candy production line

The sandwich hard candy production line is a production line that can process hard candies and sandwich candies. It can process sandwich hard candies of different weights according to requirements. The candies are neatly formed and have no bubbles on the surface.

Scope of application:

Hard candy, vitamin hard candy, vitamin filled hard candy

Sandwich hard candy production line

Production capacity Output: 660kg/h

Machine power Power: 26 Kw

Dimensions Dimension(L×W×H): 11540×1950×2400mm

5. Shaped lollipop production line

The special-shaped lollipop making machine is mainly composed of a sugar pot, a sugar storage tank, a vacuum continuous sugar pot, a rocker mixer, a sugar kneading machine, a cooling table, a thermal insulation roller bed, a stretching machine, a special-shaped lollipop forming and packaging machine, a cooling It is composed of cabinets and large vertical packaging machines.

Among them, the special-shaped lollipop forming and packaging all-in-one machine is the main equipment, which can produce dozens of three-dimensional three-dimensional special-shaped lollipops, and can make lollipops of different shapes according to customer needs.

Shaped lollipop production process:

Sugar pot → vacuum boil sugar (remove moisture) → stir, cool, add additives → knead sugar (make sugar plastic and flexible) → forming packaging → cooling → packaging → finished product.

The toffee production line adopts operations such as vacuum boiling, automatic slitting, and chain forming. The production line is mainly composed of sugar pots, storage barrels, toffee cooking pots, pouring units, and cooling tunnels. Can produce stuffed toffee, stuffed toffee (Yikoulian) and other sweets.

Features:

1 PLC automatic programming controls the sugar boiling temperature, time, pouring temperature and pouring speed;

2 9.7-inch large LED touch screen display operation;

3? Production capacity can range from 150 kg to 450 kg per hour;

4 Frequency conversion speed regulation to control the flow of sugar liquid;

5 Complete the quantitative filling and mixing of flavors, pigments and acids online;

6 Conveyor chain belt, cooling system, double demoulding mechanism demoulding;

7. Nougat candy bar production line

The main machines of the nougat row production line are the oil sugar row six-roller bed, the sugar row flattener, the sugar row cooling conveyor cabinet, the sugar row forming machine, the sugar row forming machine, and the cooling vibrating screen. The main equipment is equipped with frequency conversion speed regulation control.

Flattening machine

Function: It has the functions of automatic feeding, rolling forming, cooling, etc., and achieves continuous and uniform cooling effect.

Cooling Conveyor

Function: It has a five-layer circulating conveyor belt, which can achieve continuous and uniform cooling effect.

Sugar row forming machine

Function: It can cut the sugar belt into the rectangle, square and continuous production of the required size.

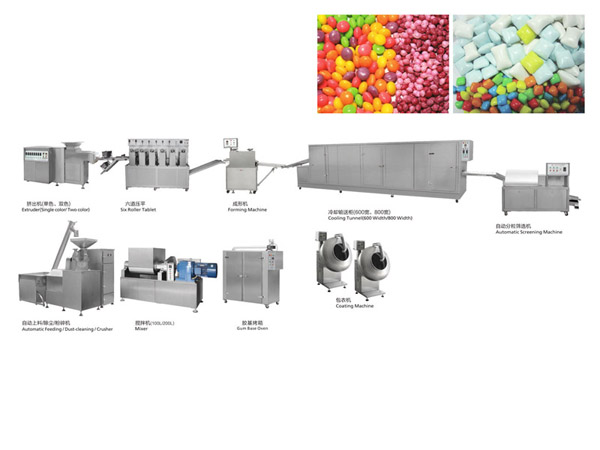

8. Chewing gum production line

The chewing gum production equipment can produce pillow-shaped chewing gum, sheet-shaped chewing gum, square granule chewing gum, ginger juice chewing gum, special-shaped chewing gum production line, rectangular chewing gum, spherical, oval, watermelon-shaped, xylitol chewing gum and other chewing gums with different tastes and shapes.

Chewing gum making machine: the main equipment is composed of mixer, extruder, six flattening, forming machine, cooling conveying cabinet, automatic granulator and coating machine.

Candies in various shapes (such as square, rectangular, sheet, etc.) can be produced. The production line is automatically controlled by PLC program.

Mixer: This equipment is used to mix and mix the raw materials for the production of chewing gum.

Extruder: This equipment is used to extrude chewing gum, and the hopper is made of stainless steel. Extrusion head water circulation heat preservation.

Pressing machine: This machine is the main equipment for producing chewing gum. It has 6 pressing rollers.

Molding machine: This machine is a chewing gum molding machine, which can produce chewing gum of different sizes according to different requirements of customers.

Polishing pot: can produce pillow gum

9. Interlayer steam stirring sugar pot

Main features of interlayer steam stirring sugar pot:

This machine adopts electric heating. It has uniform heating and easy temperature control. Stirring of ingredients Scrape bottom and sides of pan, stirring to coat. It is made of standard 304 stainless steel, it is easy to install and operate.

Scope of application:

It is widely used in food processing, such as candy, pastry, lotus seed paste, bean paste, jam, candied fruit industry.

10. Hard candy extrusion molding machine

The hard candy extrusion molding machine is suitable for the extrusion of various candies such as hard candy and nougat. The shape of the extruded sugar bar can be divided into color bar shape and sandwich shape. The production of sandwich candies requires a sandwich machine. The machine is equipped with different types of extrusion heads (double-die head and triple-die head) to extrude different forms of candy bars. The products can be divided into sandwich, color bar, or color bar sandwich. The machine can extrude continuously,

It is used together with stamping and forming equipment, and it is the main equipment for producing colored bar-shaped stamping candies.

All rights reserved:Zhi Yan Group Co., Ltd SitemapSitemapCandy making machine candy production line Toffee production line biscuit production line lollipop production line Gummy production line Popping boba production lineManufacturer