Adr :636 Yunqiao Road, Pudong New Area, Shanghai, China

Phone : +86 18221614363

Email : info@zygroups.com

Tel : +86 18221614363

1. Common materials for belt conveyors

The commonly used material for belt conveyors is glass fiber reinforced plastic composite materials. FRP is the abbreviation for glass fiber reinforced composite material. Composite materials are composed of two or more materials with different chemical or physical properties. Composite materials are divided into particle reinforcement and fiber reinforcement. FRP is based on resin and reinforced by glass fiber. It can be divided into continuous fiber and discontinuous fiber. The former is composed of laminated structure, winding structure and multi-directional weaving, and the latter is formed by pressing.

There are many molding processes of FRP. In our country, hand lay-up, pressing, winding and other processes are mostly used, while the pultrusion process is developing rapidly, and spraying and jetting processes are also used.

As the matrix and adhesive, the resin usually uses thermosetting resin, such as unsaturated polyester, epoxy resin, phenol, etc., and also uses thermoplastic resin, such as polyolefin, etc. The strength of the bonding resin and the adhesion to the fiber determine the strength of FRP The sharpness between layers, while the tensile strength and stiffness of glass fiber reinforced plastic mainly depend on the glass fiber, and the compression and bending strength are related to both.

Synthetic resin and alkali-free glass fiber are made of non-metallic materials, so that glass fiber reinforced plastic has excellent electrical insulation, wear resistance, corrosion resistance and radio wave propagation. Its physical, chemical and mechanical properties and designability are better than Steel, which can be used in the design of belt conveyors.

Second, the classification of the joints of the conveyor belt

All conveyors must be connected in a loop before use. In this way, the quality of the conveyor belt joint directly affects the durability of the belt and the smooth operation of the conveying process. There are three general methods of conveyor belt joints, namely mechanical joints, cold bonded joints, and hot vulcanized joints.

Mechanical joint method

Generally speaking, this refers to the joint of the belt conveyor belt. This joint method is convenient and economical, but the joint is low in efficiency and easy to damage. It has a certain impact on the service life of the conveyor belt product. PVC and PVG flame retardants and antistatic conveyor belts are located between the common joints of conveyor belts below grade 8.

Cold head method

The cold head method is to use cold bonding adhesive for the joint. This joint method is more effective and economical than the mechanical joint of the car-made roller, and it should have a better joint effect. However, starting from the actual situation, due to the difficult process conditions Master, it has a great influence on the quality of the mixture, so the influence on the joint is not very stable.

Hot vulcanization joint method White sugar processing plant

Practice has proved that the thermal vulcanization joint method is an ideal joint method, which not only guarantees the high efficiency of the joint, but also ensures the stability of the joint, long life, and convenient operation, but it has disadvantages such as cumbersome process, high cost, and long connection time.

Third, the use and maintenance of the conveyor belt using the assembly line

The assembly line transportation is widely used in various industries due to its simple structure, convenient operation and strong transportation capacity. In industrial production, if the belts of the assembly line are properly maintained and maintained, the service life of the assembly line can be extended, thereby effectively reducing the production cost.

1. With the popularization of assembly lines in industrial production, multi-variety, high performance, lightweight, multi-function, and long life are several aspects that manufacturers pay attention to. The following items should be paid attention to in the use of the conveyor belt of the assembly line:

1. Avoid the rollers being covered by the material, causing the rotation failure, prevent the leakage of the material from getting stuck between the roller and the tape, pay attention to the lubrication of the movable part of the conveyor belt, but not oil the conveyor belt;

2. Prevent the assembly line load from starting;

3. If the conveyor belt is off-track, measures should be taken to correct it in time;

4. When the conveyor belt is found to be partially damaged, it should be repaired in time to avoid expansion;

5. Prevent the conveyor belt from being blocked by the frame, pillar or block material, and prevent it from breaking and tearing.

conveyor

2. In industrial production, saving production costs is the key, so the conveyor belt must be properly maintained, which can effectively extend the service life of the assembly line.

1. Conveyor belts should be kept clean during transportation and storage, avoid direct sunlight or rain and snow, prevent contact with acids, alkalis, oils, organic solvents and other substances, and be one meter away from heating devices.

2. When the conveyor belt is stored, the warehouse temperature should be kept between 18-40 ℃, and the relative humidity should be kept between 50-80%.

3. During the storage period of the conveyor belt, the products must be placed in rolls without being folded, and the conveyor belt should be turned once every season.

4. Conveyor belts of different types and specifications are not suitable to be connected together, and their joints are glued.

5. The type, structure, specification and number of layers of the conveyor belt should be selected reasonably according to the conditions of use.

6. The operating speed of the conveyor belt should generally not be greater than 2.5m/s, and the material with large lumpiness and abrasion and the unloading device using fixed pears should be as low as possible.

7. The feeding direction should follow the running direction of the conveyor belt. In order to reduce the impact of the material on the conveyor belt when the material falls, a chute should be used to reduce the material falling distance; the conveyor belt material receiving section should shorten the distance between the rollers and adopt buffer rollers. For material leakage, the conveyor belt should adopt a soft and moderate baffle plate to prevent the baffle plate from being too hard and scratching the belt surface of the conveyor belt.

Fourth, the main feature of the hydraulic support for the sugar making equipment is the core technology of the sugar making equipment

The single hydraulic prop of the sugar-making equipment uses the hydraulic pressure to generate working resistance and realize the lifting and unloading of a single collapsible prop.

1. Large work schedule and low safety management cost

Each specification can replace 2-4 specifications of traditional piston type single pillars, reducing the frequency of changing different types of single pillars due to changes in the height of the working face and the amount of movement of the roof and bottom of the roadway, reducing the labor intensity of workers And additional spare number of pillars.

2. High supporting strength, good safety and stability

The pillar has no load-bearing welding seam, and the pillar adopts the principle of suspension technology. The suspension force generated by the high-pressure liquid directly acts on the end of the top cover, reaching four-fifths of the working resistance, and the force on the column is only one-fifth, which greatly improves the pillar. Support stability and unbalanced load capacity.

3. Leaks are easy to find, safe and reliable, and high performance

Due to the structural improvement, the false top and de-topping of the pillar caused by internal leakage are avoided. Once the pillar leaks, it can be directly checked by the naked eye at the underground site, and the pillar can be replaced at any time; the principle of sealing compensation and sealing tightening technology is adopted. , The greater the pressure on the top plate, the tighter the sealing surface fits, and the less likely it is to leak.

4. Long service life, easy operation and maintenance

The overall structure is simple, and the service life is long; it is easy to operate, easy to maintain, and can greatly reduce the rate of pillar lifting and maintenance.

Five, case

KESEM sugar factory in Africa

Thailand KSL Happy Sugar Factory

ZTE Energy (Inner Mongolia) Co., Ltd.

Nanning Liangqing East Sugar Sugar Industry Co., Ltd.

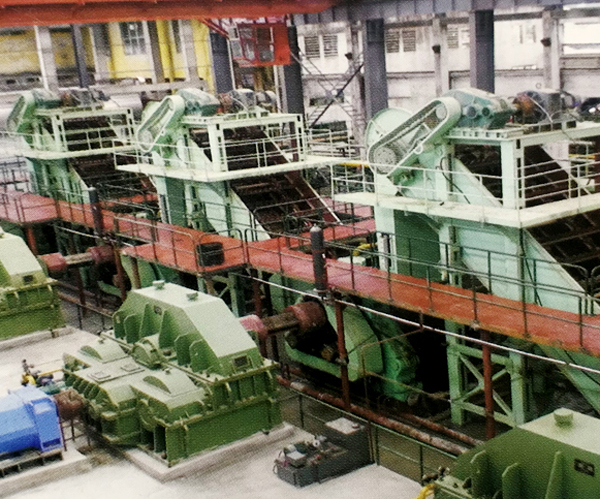

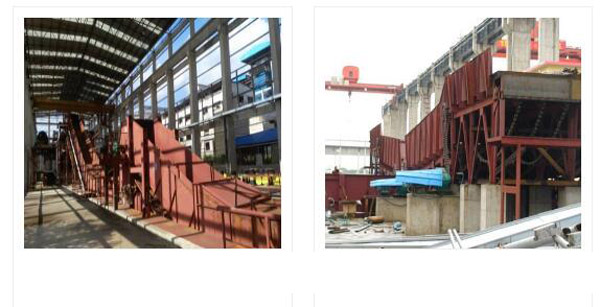

6. Factory production base Refined sugar processing machine

Main products: Our company produces 500-25000 tons/day sugarcane squeezing equipment and accessories. The main products are: various specifications of squeezers, sugarcane conveyors, rake-tooth conveyors, sugarcane weighing tables, sugarcane feeding tables, tearing Machine, sugarcane juice trommel, high-speed belt, squeezer lower feeding roller and front and rear upper feeding roller device, double-roll feeder, etc.;

Capability: It has more than 400 sets of various processing equipment, and produces more than 300 sets of various types of presses and pretreatment equipment.

Human resources: more than 260 employees, 46 professional and technical personnel, including 2 senior titles, 8 intermediate titles, and 38 other types of technical personnel.

Business philosophy: The needs of users are our pursuit!

Quality policy: first-class quality, high-efficiency service, keep users satisfied!

Quality Assurance: The company has passed ISO9001:2015 quality system certification, strictly controls and manages all links related to product quality, and uses world-class testing equipment to implement incoming and outgoing inspections of raw materials and finished products. We have passed the "people, The multi-point and all-round control of "machine, material, method, environment, and measurement" ensures that it can provide users with continuous and stable qualified products.

After-sales service: The company provides convenient and fast localized after-sales technical services. The service center has established a complete organizational structure and after-sales service process in accordance with ISO requirements to ensure the effectiveness, timeliness and comprehensiveness of technical support and after-sales service.

white sugar processing machine

7. Sugarcane processing equipment

1. Press series

Inclined Press (TSG)

Gear and coupling series

Tearing machine

Equipped with light twin-roll feeder press

Inclined press

Constant ratio press

Press machine

Large rock sugar processing machine

2. Sugarcane conveyor series

Sugarcane conveyor

Feeding table

Sugar Processing machine

3. Intermediate conveyor series

Rake tooth conveyor

4. Roller screen series

Cane Sugar processing plant

5. New type lower feed roller

6. Tear-off machine series

White sugar syrup processing machine

7. Press roll series

8. Copper bearing series

9. Gear/coupling series

Sugarcane processing machine

10. Equipment accessories

Beet sugar processing machine

All rights reserved:Zhi Yan Group Co., Ltd SitemapSitemapCandy making machine candy production line Toffee production line biscuit production line lollipop production line Gummy production line Popping boba production lineManufacturer