![]()

Adr :636 Yunqiao Road, Pudong New Area, Shanghai, China

Phone : +86 18221614363

Email : info@zygroups.com

Tel : +86 18221614363

processing capacity:500-5000dun/day

Application scope:beet

Product introduction:

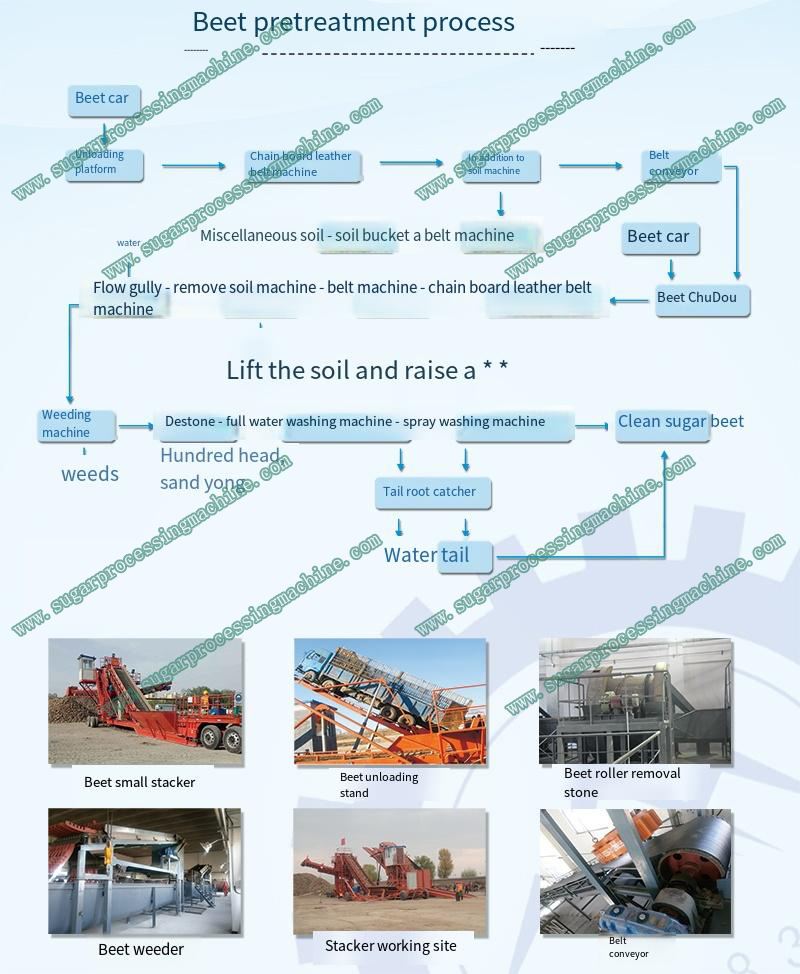

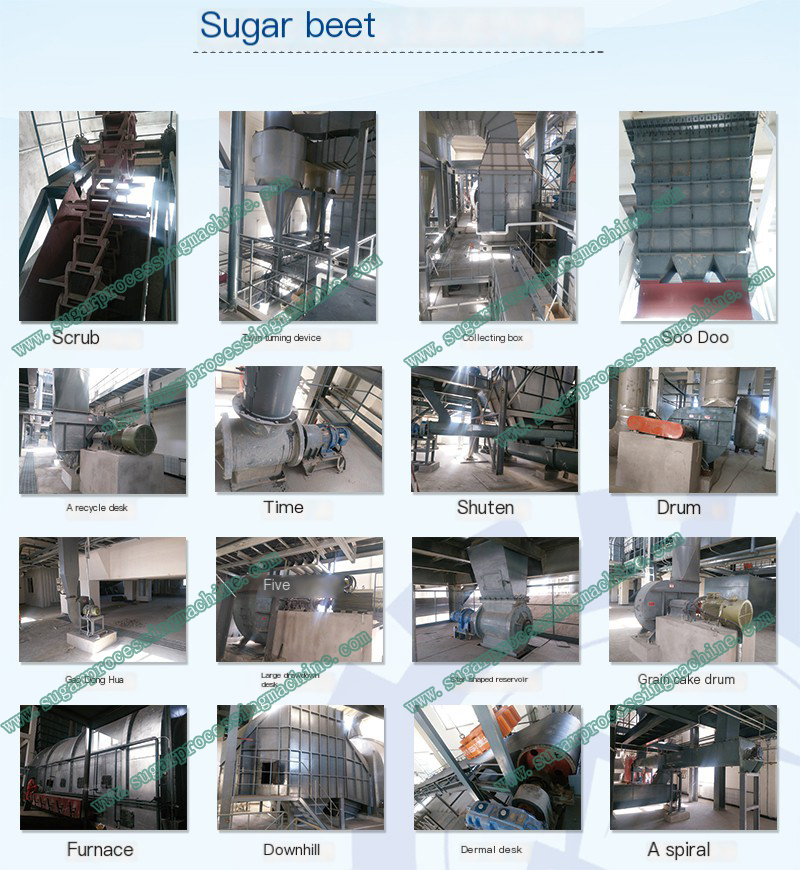

Beet sugar processing process

Freshly washed and sliced beets: Remove rocks and weeds before washing the beets. The washed beetroot is then cut into thin noodles, called shredded beet, and sent to the extraction system.

Beet sugar processing process

Freshly washed and sliced beets: Remove rocks and weeds before washing the beets. The washed beetroot is then cut into thin noodles, called shredded beet, and sent to the extraction system.

Sugar extraction: Soak in hot water to remove substances. The syrup is then heated, and lime and carbon dioxide are added to remove remaining impurities.

Making sugar (purification-crystallization-drying)-filtering, evaporating and concentrating, crystallizing and drying the purified fruit juice. It is then stored in a silo until it is packaged and shipped.

1. Beet Stacker

Due to the in-depth mechanized harvesting of sugar beets in recent years, it has brought convenience and also brought many inclusions into the pile of sugar beets, which caused the actual weight of the sugar beets to be too high after loading. At the same time, after the debris enters the beet stack, it causes the microbes to multiply. The beet has deteriorated before it enters the production line. Sometimes it will cause the loss of tens of thousands of tons of beet and cause great economic loss to the sugar factory.

This equipment solves the above problems well, and it has been effective for semi-trailer heavy trucks, medium trucks, agricultural vehicles, dump trucks, etc.

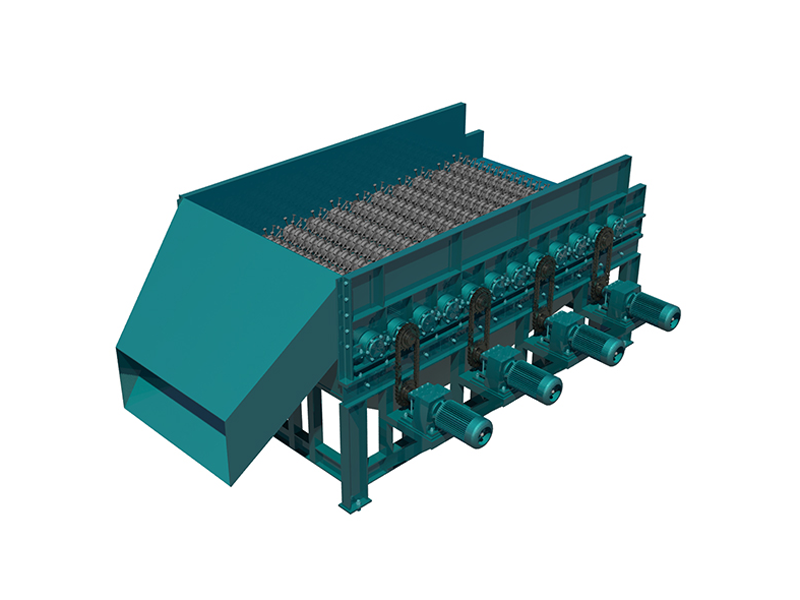

2. Sugar beet soil remover

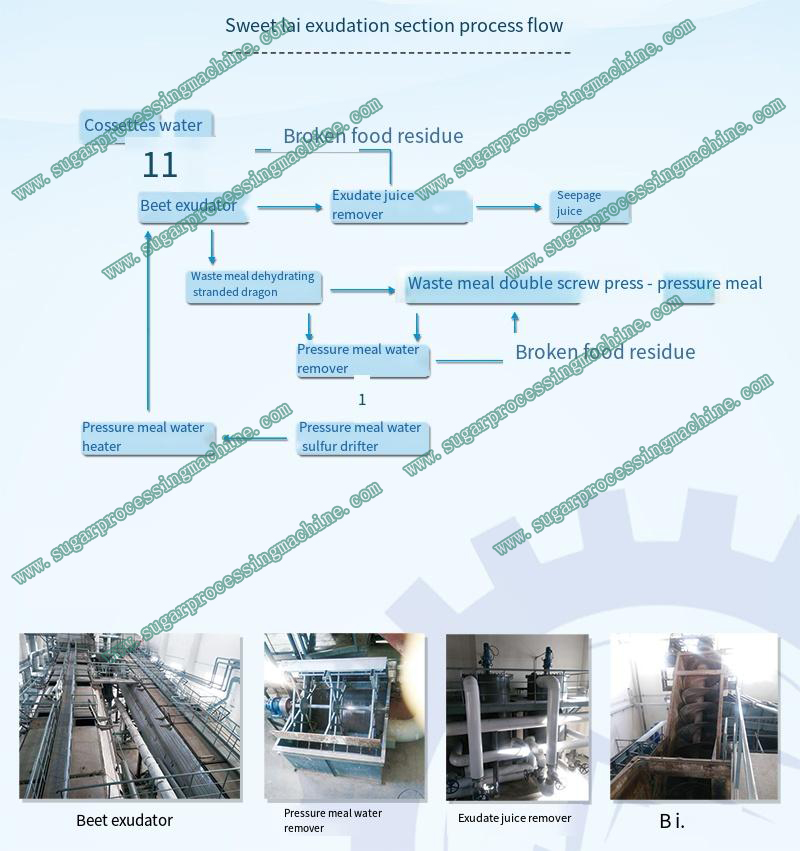

Beet exudator

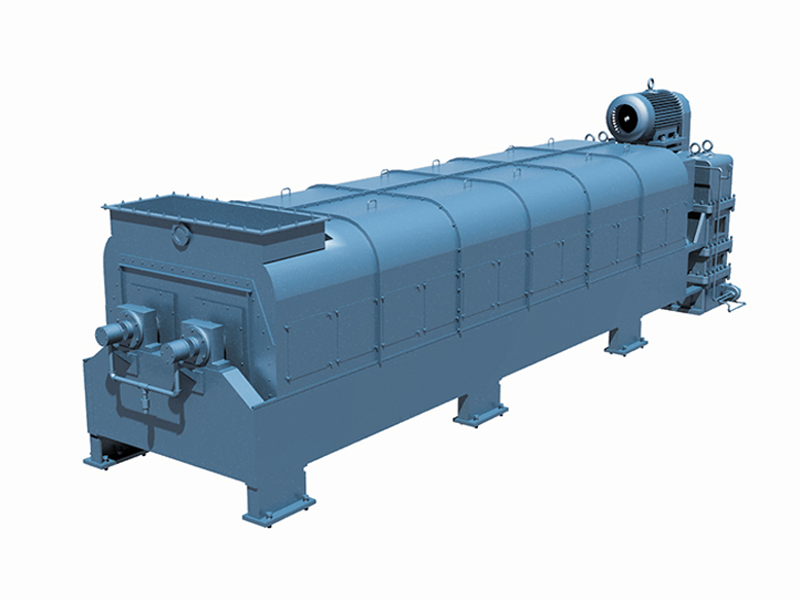

The sugar beet exudator produced by our company has three specifications of 1500T/D, 2000T/D and 3000T/D, with an over-production capacity of up to 20%. It is a horizontal continuous type (Dds type) and is the equipment of choice for beet sugar mills.

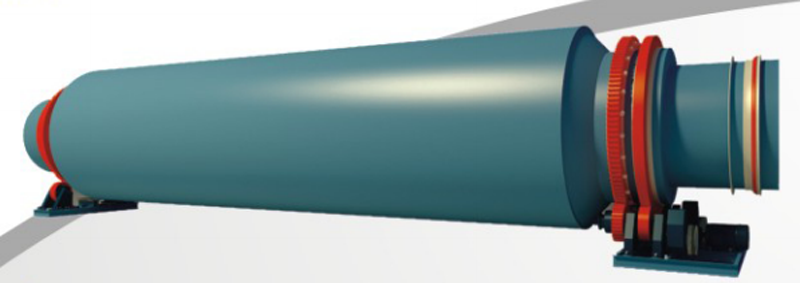

Sugar beet waste drum dryer system

This system is a system with a larger capacity. The actual production capacity can reach 4,700 tons per day. It has the characteristics of energy saving and environmental protection, high evaporation efficiency, high degree of automation, large production capacity and low failure rate.

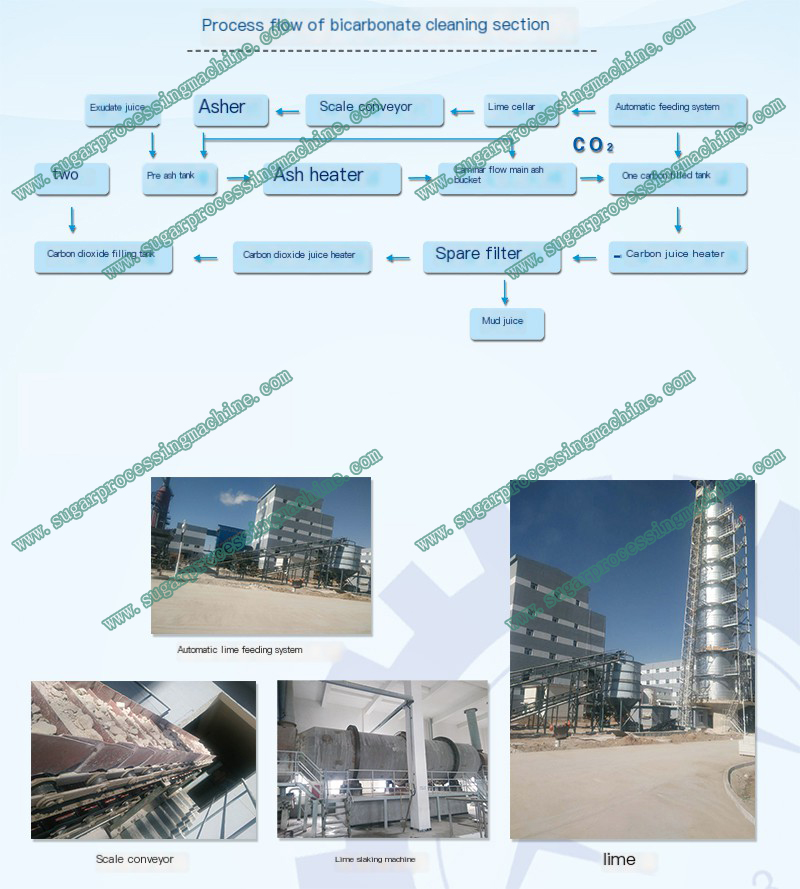

Closed positive pressure high efficiency lime kiln

The closed positive-pressure high-efficiency lime kiln produced by our company has two types of vertical feeding and inclined bridge feeding. It adopts double-hat kiln seal structure with high kiln gas content and isobaric blast full positive pressure operation. The calcination efficiency is high, the rotating distributor cloth avoids partial burning, the spiral ash discharging machine continuously discharges the ash, and the star ash discharging machine discharges the ash uniformly. It adopts flameless electronic ignition and PLC control automatic feeding, which can save a lot of labor. The product specifications are 120m2, 200m2, 250m2, 270m2, 350m2, and 400m2, and can be specially designed according to user needs. The company provides a full set of equipment and technical training.

Lime disintegrator (ash disintegrator)

The lime dispersing machine produced by our company includes three standard counter-flow dispersing machines, downstream dispersing machines, and inner sleeve type dispersing machines. The product has high production efficiency, few failures, safety and reliability, and is a product needed by carbonic acid production sugar factories and chemical manufacturers. Product specifications and production capacity are φ1500 (1500t/h), φ1800 (3000t/h), φ2200 (4000t/h), φ2500 (6000t/h).

Internal circulation carbonation filling tank

The reasonable degree of the filling tank structure is a crucial factor for the absorption of CO2 during the filling process. It is the wish of each sugar factory to seek a high absorption rate. The carbonation filling tank produced by our company is a belt developed and designed based on experience. Full filling equipment for internal circulation wells and gas scrapers. The gas distribution is even, the absorption rate is good, and the gas pipe is automatically cleaned. Products with different specifications can be designed according to user needs.

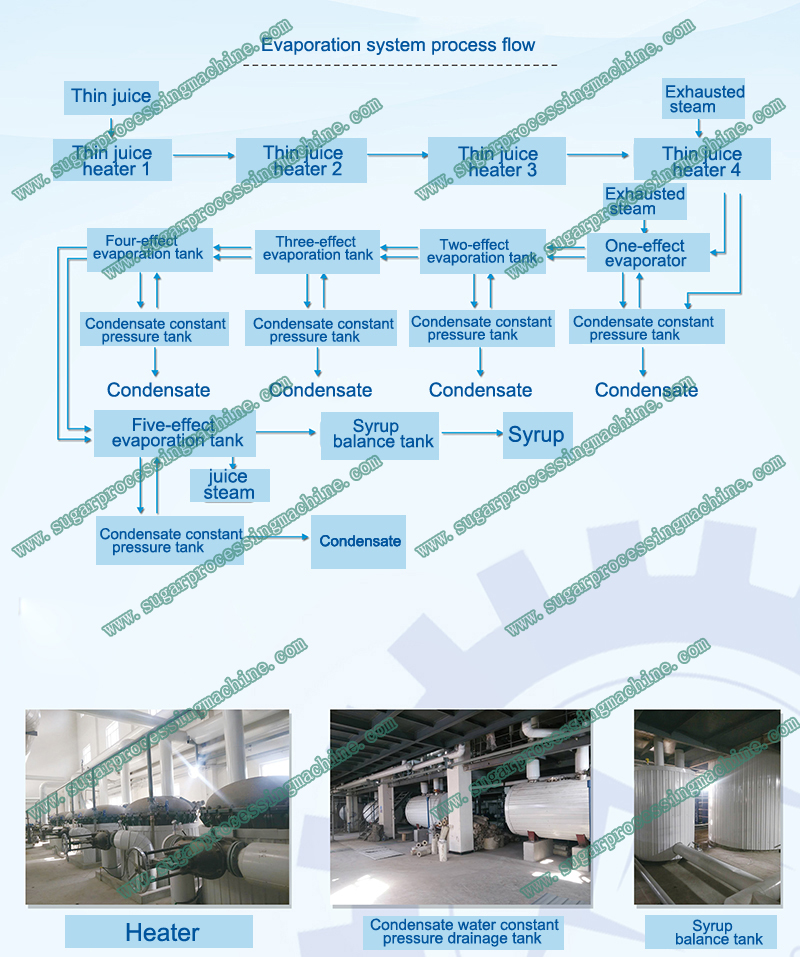

Sugar beet processing raw sugar evaporation tank system machine

The evaporator produced by our company has an internal circulation structure. Its main feature is to reduce the bottom volume and the juice outlet pipe is closed to effectively separate the juice from the juice outlet.

The evaporator produced by our company has a variety of different specifications of heating area, reasonable structure and high heat transfer efficiency. The thickness of the scale is greatly reduced, and the thermal resistance is greatly reduced; at the same time, some parts are made of special materials, which greatly improves the use time, and the improvement of the structure reduces the residence time of the sugar water. The evaporation tank produced by our company has large production capacity, low sugar loss, little increase in sugar water pigment, and long tank washing cycle. The specifications are 550m2, 750m2, 1000m2, 1200m2, 1400m2, 1600m2, 1800m2, 2000m2, 2200m2, 2500m2, 3000m2, 3500m2, 4000m2, and 5000m2.

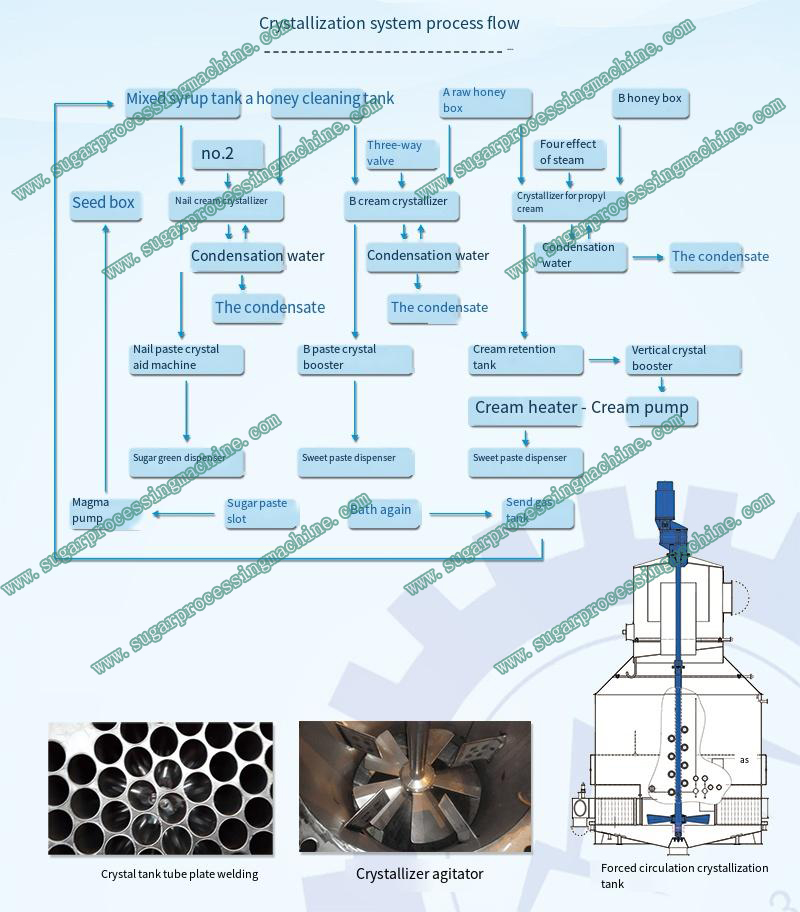

Vertical crystallizer

The crystallization of the final massecuite is a very important part of each sugar factory. The quality of the crystallization effect directly affects the total loss of the process. The vertical crystallizer developed by our company has changed the structure of the traditional horizontal crystallizer, dynamic stirring and static cooling, and continuous operation of the upper and lower multi-layer large-area cooling, which solves the problem of uneven cooling temperature of the horizontal crystallizer. The equipment adopts hydraulic transmission, with small mechanical wear, less failure, low noise, and has the characteristics of small floor space. The specifications are 80m3, 100m3, 150m3, 200m3, 400m3.

Vertical continuous crystallization tank

The equipment uses low-efficiency sugar-making steam to cook sugar, and is equipped with a full set of automatic control devices. The operation process is safe and reliable, with high automation and simple and convenient operation. It is an energy-saving and consumption-reducing equipment in the sugar industry. The vertical continuous crystallization tank has the characteristics of compact design structure, reasonable overall layout, and small installation area.

Horizontal crystallizer

Horizontal crystallizer is a product improved by our company on the basis of synthesizing the original crystallizer. This equipment is divided into two types (U-shaped groove) and fully enclosed (cylindrical type). The stirring shaft is divided into two types: spiral belt type and elliptical frame type. Simple structure, convenient maintenance, good coaxiality, flexible rotation of the stirring shaft, etc. Especially the special sealing form of the lubricating part provides quality assurance for refined sugar production. The specifications are 20m3, 30m3, 40m3, 45m3, 55m3, 60m3.

Horizontal continuous crystallization tank

The horizontal continuous crystallization tank produced by our company has good massecuite circulation, improved heat utilization rate, saved equipment investment, simple and convenient operation, and created good conditions for the continuity and automation of sugar production.

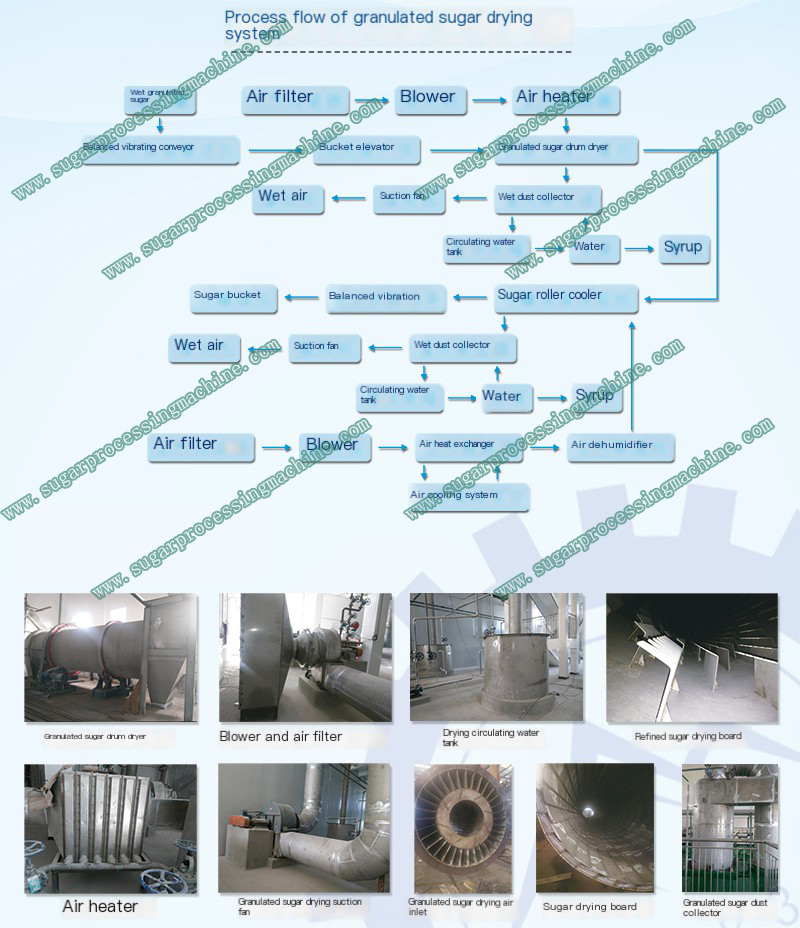

Drum dryer machine cooling machine

The drum dryer produced by our company has two types of equipment: sugar dryer and marshmallow dryer. The structure has two types of drying, cooling integrated machine and split machine. The product specifications can meet the needs of sugar factories of various scales, especially in recent years. The stainless steel lined drum dryer developed in the past few years is reliable in operation and has become a frequently equipped equipment for soft white sugar manufacturers, and it is also the equipment required for the production of refined soft white sugar and large-capacity sugar manufacturers. Specifications and production capacity are 1600 (15T/H), 1800 (20T/H), 2200 (30T/H), 2500 (40T/H), 2750 (50T/H), 3200 (70T/H). The company can provide a complete set of process equipment such as air filtration, air heating, air cooling, air dehumidification, etc.

.Sugar drying and cooling integrated machine

Refined sugar drying and cooling integrated machine The company's refined sugar drying and cooling integrated machine, the product specifications can be adapted to sugar factories of various sizes, with high drying efficiency and good sealing. The grain wear is small, the floor space is small, and the degree of automation is high. It can provide a complete set of selection and matching of air filtration, heating, cooling and dehumidification. Specifications are 20T/H, 30 T/H, 40 T/H, 50 T/H.

All rights reserved:Zhi Yan Group Co., Ltd SitemapSitemapCandy making machine candy production line Toffee production line biscuit production line lollipop production line Gummy production line Popping boba production lineManufacturer